In the fast-paced world of garment manufacturing, maintaining high-quality standards and meeting production deadlines are paramount. Inline inspection has emerged as a crucial step in the production process, offering numerous benefits for both manufacturers and customers. In this blog, we will delve into the concept of inline inspection in garment industry, its significance, and how it helps enhance quality and efficiency.

Understanding Inline Inspection in Garment Manufacturing

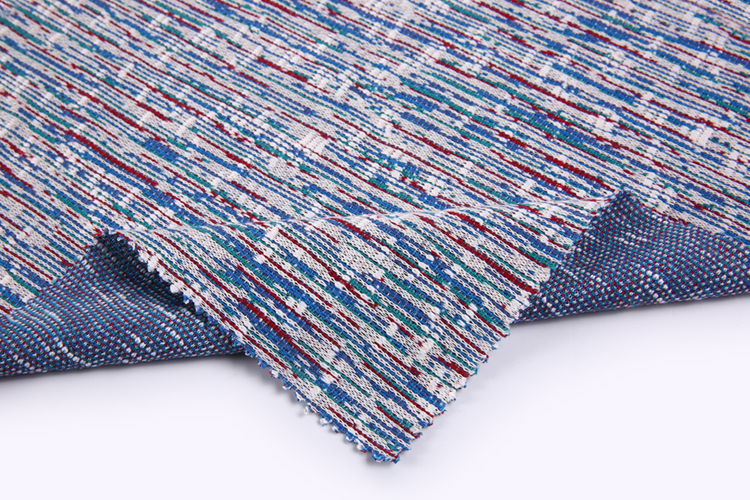

Inline inspection, also known as in-process inspection, is a quality control process that occurs during the garment manufacturing process, rather than at the end. At various stages of production, trained inspectors conduct checks to identify and rectify defects promptly. These stages can include cutting, sewing, printing, and finishing, ensuring that each step adheres to the desired quality standards. By implementing inline inspection with the assistance of textile inspection services, manufacturers can detect and correct any issues early on, minimizing the risk of producing garments with quality issues and ensuring customer satisfaction.

The Importance of Inline Inspection for Quality Assurance

- Early Detection of Defects: Inline inspection allows for the early identification of defects and issues, reducing the risk of producing a large number of faulty garments. This leads to significant cost savings as it minimizes the need for rework or scrapping of entire batches.

- Process Improvement: With inline inspection, manufacturers can identify bottlenecks and inefficiencies in the production process. By addressing these issues promptly, they can optimize workflow and achieve better overall efficiency.

- Consistency and Compliance: Inline inspection ensures that each garment adheres to the required quality and safety standards consistently. This helps maintain brand reputation and compliance with customer requirements and industry regulations.

Implementing Inline Inspection: Best Practices

- Trained Inspectors: Employ skilled and trained inspectors who have a keen eye for detail and a thorough understanding of garment quality standards. Their expertise ensures accurate and reliable assessments.

- Clear Inspection Criteria: Establish clear and specific inspection criteria for each stage of production. This will help standardize the evaluation process and enable inspectors to focus on critical areas.

- Collaboration with Production Team: Encourage collaboration between the inspection team and the production team. Feedback from inspectors can help the production team understand the recurring issues and take corrective actions proactively.

Inline Inspection in the Age of Technology

In recent years, technology has revolutionized inline inspection in garment industry. Automation and digitalization have streamlined the process, making it even more effective and efficient. Here's how technology plays a crucial role:

- Machine Vision Systems: Advanced machine vision systems can inspect garments at high speeds, detecting defects that are difficult to identify with the naked eye. This technology ensures a higher level of accuracy and consistency in inspection.

- Data Analytics: By leveraging data analytics, manufacturers can gain valuable insights from inspection data. Patterns and trends can be identified, enabling proactive measures to address quality issues and improve production processes.

Inline inspection in garment industry has emerged as an indispensable aspect of the garment manufacturing process, ensuring high-quality products and streamlined production. Its early defect detection capabilities, process improvement benefits, and consistent quality assurance make it an essential practice for garment manufacturers looking to meet customer demands and remain competitive in the industry. Embracing technology and best practices in inline inspection can help manufacturers elevate their operations, delivering superior garments that meet the highest standards of quality and customer satisfaction.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.