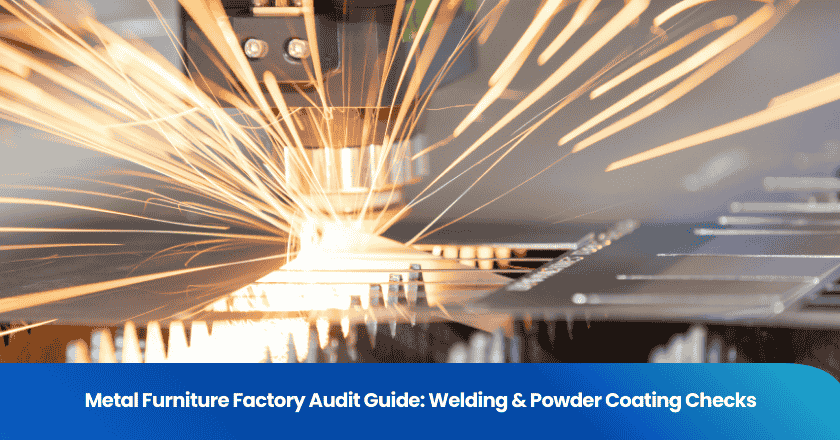

A comprehensive factory audit is essential for ensuring that metal furniture meets the durability and aesthetic standards expected by consumers. Auditors prioritize two critical areas: welding quality and powder coating adhesion. These elements directly impact the structural integrity and corrosion resistance of the final product. Industry data consistently shows that defects in these areas—such as weak welds or peeling paint—are the leading causes of product returns and warranty claims.

| Defect Type | Impact |

|---|---|

| Surface Defects | Ruins aesthetic appeal (scratches, uneven coating) |

| Structural Issues | Compromises safety (weak welds, instability) |

| Finish Problems | Leads to rust and peeling (poor adhesion) |

Key Takeaways

- A thorough factory audit validates manufacturing processes, reducing defect rates.

- Mechanical strength testing of welds confirms that furniture can withstand daily stress loads.

- Powder coating quality control ensures finishes are durable and rust-resistant.

- Proper surface preparation (cleaning/sanding) is the most critical factor for coating adhesion.

- Regular equipment maintenance prevents production downtime and inconsistent quality.

Metal Furniture Factory Audit Scope

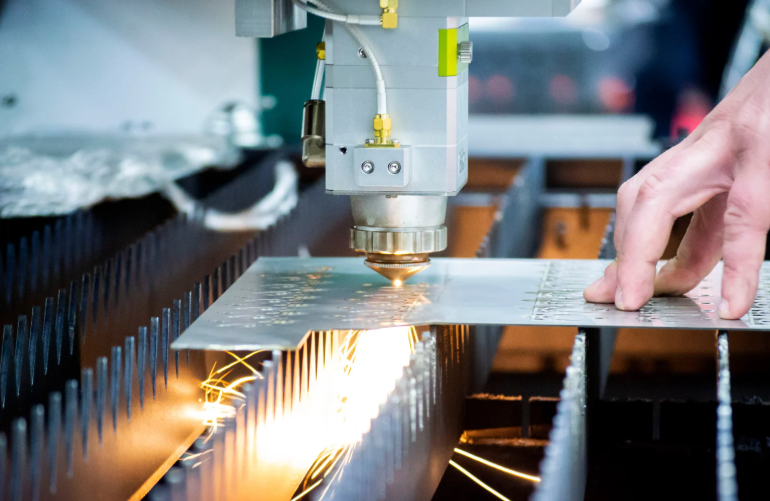

Production Line and Equipment

Auditors verify that the factory utilizes appropriate machinery, such as robotic welding arms or calibrated powder coating guns. They check maintenance logs to ensure equipment is regularly serviced. Well-maintained machines are crucial for producing consistent welds and uniform coating thickness.

Quality Management Systems

A robust Quality Management System (QMS), typically ISO 9001 certified, is the backbone of reliable manufacturing. Auditors assess whether the factory follows documented procedures for incoming material checks, in-process inspections, and final product testing.

| Standard | Focus Area |

|---|---|

| EN 12520 | Strength and safety for domestic seating |

| EN 581-1 | Safety for outdoor furniture |

| ASTM F1561 | Performance of outdoor plastic chairs |

Welding Quality Assessment

Welding integrity is non-negotiable for safety. Weak joints can lead to catastrophic failure. Auditors employ both visual checks and mechanical tests to verify weld strength.

Mechanical Strength Testing

Inspectors perform destructive and non-destructive tests to measure weld durability.

| Test Type | Description |

|---|---|

| Tensile Testing | Pulls the joint apart to measure breaking force. |

| Bend Test | Bends the sample to check ductility and joint integrity. |

| Penetrant Testing | Uses dye to reveal surface cracks invisible to the eye. |

Common Welding Defects

Visual inspection identifies common flaws that weaken the structure:

- Porosity: Tiny holes caused by trapped gas.

- Undercut: A groove melted into the base metal, reducing thickness.

- Spatter: Metal droplets that ruin the finish.

- Incomplete Fusion: The weld metal hasn't bonded with the base.

Tip: Regular welder training is the most effective way to reduce these defects.

Powder Coating Quality Control Testing

For metal furniture, powder coating provides essential protection against rust. QC protocols focus on adhesion and thickness to ensure longevity.

Adhesion and 3M Tape Test

The "Cross-Hatch" or 3M Tape Test (ASTM D3359) is the industry standard for checking adhesion. Inspectors cut a grid pattern into the coating, apply pressure-sensitive tape, and pull it off. The amount of paint removed determines the rating (0B to 5B, with 5B being perfect adhesion).

Critical factors for adhesion:

- Surface Prep: Sandblasting or chemical cleaning to remove oil/rust.

- Curing: Correct oven temperature and time.

- Cleanliness: Dust-free environment during application.

Abrasion and Corrosion Resistance

To verify durability, especially for outdoor furniture, auditors conduct salt spray tests (ASTM B-117). Samples are exposed to a saline fog for 24-48 hours (or more) to check for rust formation. Abrasion tests simulate daily wear to ensure the coating doesn't wear through easily.

Visual and Thickness Inspection

Inspectors measure coating thickness using a digital gauge. The ideal range balances protection and flexibility.

| Application | Typical Thickness |

|---|---|

| Indoor Furniture | 60 – 80 microns (2.4 – 3.2 mils) |

| Outdoor/Industrial | 80 – 120 microns (3.2 – 4.8 mils) |

Note: Coatings that are too thick can be brittle and prone to chipping, while thin coatings offer insufficient protection.

Audit Checklist and Best Practices

On-Site Inspection Steps

A structured approach ensures no detail is missed:

- Material Check: Verify steel/aluminum grade and thickness upon arrival.

- Welding Check: Inspect joints before finishing; perform spot strength tests.

- Finishing Check: Measure coating thickness and perform cross-hatch adhesion tests.

- Assembly Check: Ensure parts fit correctly without force; check stability.

A successful metal furniture factory audit hinges on verifying two pillars: structural safety through welding checks and surface durability through coating tests. By rigorously implementing these inspections, buyers can secure high-quality products that withstand the test of time, reducing returns and protecting their brand reputation.

FAQ

What is the purpose of a metal furniture factory audit?

A factory audit verifies that a manufacturer has the capability, equipment, and quality systems to produce safe, durable metal furniture consistently.

How do inspectors test welding quality?

They use visual inspection for surface defects and mechanical tests (like load-bearing or destructive pull tests) to ensure joint strength meets safety standards.

Why is powder coating adhesion important?

Good adhesion prevents the finish from peeling or chipping, which exposes the metal to rust. It is essential for the product's longevity and aesthetic appeal.

What is the standard test for coating adhesion?

The Cross-Hatch Adhesion Test (ASTM D3359), often called the tape test, is the most common method for verifying paint bond strength on metal surfaces.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.