In the global home textile industry, thread count has long been the primary metric for defining the quality, luxury, and durability of bed linens. However, the technical definition of thread count—the total number of warp and weft yarns interlacing within a single square inch of fabric—is often obscured by aggressive marketing tactics. For procurement managers and quality engineers, absolute accuracy in verification is essential to ensure that the physical product aligns with the technical specifications. Laboratory-based quantitative analysis, supported by international standards like ASTM D3775, provides the only objective method to deconstruct fabric density and validate material integrity. Understanding the laboratory protocols for thread counting is critical to mitigating the risks of supplier non-compliance and ensuring long-term consumer satisfaction.

Key Takeaways

- Thread count is a metrological measurement of weaving density, combining warp (longitudinal) and weft (transverse) yarns per square inch.

- Standardized testing protocols (ASTM D3775 and ISO 7211-5) are mandatory for objective quality validation.

- The 'Ply' of a yarn refers to the number of individual strands twisted together; ASTM standards dictate that each multi-ply yarn counts as one thread.

- Optimal balance for durability and breathability is typically found between 300 and 500 TC; counts exceeding 600 often indicate inflated figures through multi-ply yarns.

- Professional quality checks must include specimen conditioning in a controlled environment to ensure yarn tension does not skew results.

- Third-party quality assurance is required to verify claims of long-staple Egyptian or Supima cotton against cheaper substitutes.

The Metrological Basis of Fabric Density

Thread count analysis is a fundamental aspect of textile metrology. It quantifies the 'tightness' of the weave, which directly impacts the fabric's porosity, tensile strength, and tactile smoothness. In a professional laboratory setting, the process begins with 'Conditioning'—the specimen is placed in a standard atmosphere (typically 21'C at 65% relative humidity) for 24 hours. This ensures that moisture regain is consistent, as cellulosic fibers like cotton swell when damp, which can artificially increase the thread count per linear inch.

Warp vs. Weft Interlacing

The total count is the sum of the Warp (ends) and Weft (picks). Warp yarns are held under high tension on the loom, while weft yarns are inserted across. High-quality industrial bedding utilizes a balanced construction where the warp-to-weft ratio is approximately 1:1, ensuring the fabric remains dimensionally stable after multiple industrial laundry cycles.

| Technical Feature | Sateen Weave (Luxury) | Percale Weave (Classic) |

|---|---|---|

| Weave Structure | Four over, one under | One over, one under |

| Tactile Property | Silky, high luster | Crisp, matte finish |

| Porosity (Breathability) | Lower (Tighter surface) | Higher (More airflow) |

| Pilling Resistance | Moderate | Excellent |

Laboratory Methods for Quantitative Thread Counting

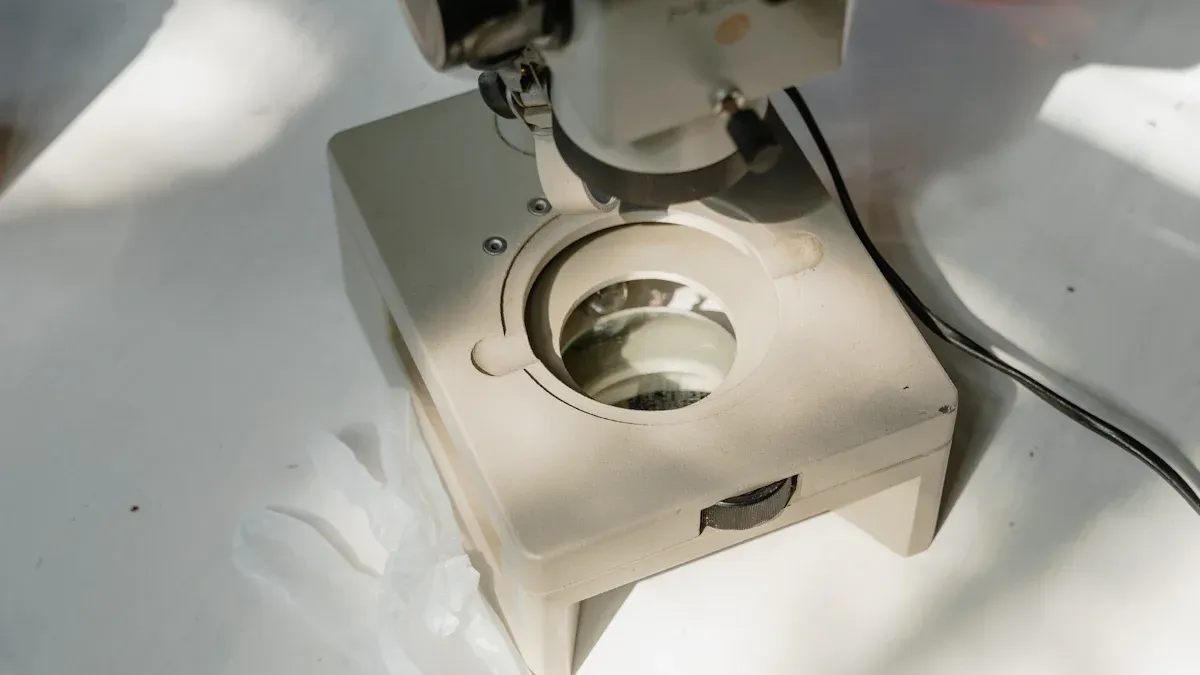

To verify compliance with a buyer's tech pack, technicians utilize specialized optical and digital instruments. The most common tool is the Thread Counting Glass (Linen Tester), which provides 10X magnification and a calibrated aperture. For high-volume textile quality control, digital pick counters and computer vision systems are employed to eliminate human error.

ASTM D3775: The Industrial Standard

ASTM D3775 is the definitive test method for the fabric count of woven fabrics. The protocol requires five separate measurements taken across the width of the fabric (excluding the selvage). The average of these five readings constitutes the official thread count. This method prevents a supplier from 'cheating' by increasing yarn density only at the edges of the roll.

| Instrument | Technical Principle | Advantage |

|---|---|---|

| Linen Tester (Manual) | Fixed-magnification optical lens | Cost-effective for on-site audits |

| Digital Pick Counter | Scanning laser/CCD sensor | Highest precision; eliminates eye strain |

| Digital Image Analysis | Fourier Transform (FFT) algorithms | Analyzes complex jacquard or twill weaves |

Technical Note: For fabrics with very high counts (e.g., 500+), the threads are often too fine for manual counting. In such cases, technicians use 'Yarn Stripping,' where they physically unravel one square inch of fabric and count each yarn individually.

The 'Ply' Trap: Identifying Marketing Inflation

The most frequent technical dispute in bedding procurement involves 'Ply.' Ply refers to the number of single yarns twisted together to form a single thread. A common tactic for unscrupulous suppliers is to use a 4-ply yarn and count each strand as a separate thread. For example, a fabric with 200 warp yarns and 200 weft yarns of 2-ply construction is marketed as '800 Thread Count' (400 x 2).

According to current **FTC (Federal Trade Commission)** and **ASTM** guidelines, this is a misleading practice. A thread is defined as the structural unit that is interlaced; therefore, regardless of the ply, it should be counted as one. High-quality single-ply yarn made from long-staple cotton is technically superior to multi-ply yarn made from short-staple waste fibers, even if the latter claims a higher numerical count.

Material Integrity: Staple Length and Cotton Grade

Thread count alone is a poor indicator of longevity. The durability of a sheet is technically determined by the 'Staple Length' of the cotton fiber. Long-staple (LS) and Extra-Long Staple (ELS) fibers, such as Giza 45 or Supima, allow for the spinning of thinner, stronger yarns. These yarns can be woven into a high thread count without making the fabric feel stiff or heavy.

- ELS Cotton: Staple length > 1.375 inches. Results in fewer fiber ends, reducing pilling.

- Standard Cotton: Staple length < 1.1 inches. Requires higher twist and thicker yarns, leading to a coarser hand-feel.

- Yarn Linear Density: Measured in Ne (English Cotton Count) or Tex. A higher Ne (e.g., 80s or 100s) indicates a finer yarn suitable for high TC fabrics.

Verification of these claims requires a technical product inspection where fiber samples are analyzed under a microscope or through DNA testing to confirm geographical origin.

Interpreting official Lab Reports for Procurement

A professional lab report from an ISO 17025 accredited facility is the final safeguard. When reviewing a report, engineers look for the following data points:

- Threads per 10cm or Inch: The raw count data for both directions.

- Yarn Type and Ply: Verification of single-ply vs. multi-ply construction.

- Dimensional Stability: Shrinkage results (ISO 6330) after 5 cycles, which indicates if the high TC will be maintained after use.

- Tensile/Bursting Strength: Confirming that the tight weave has not rendered the fabric brittle.

| Fiber Source | Standard Purity Check | Impact on TC Accuracy |

|---|---|---|

| Egyptian Cotton | Cotton Egypt Association Certification | Ensures yarn fineness aligns with count |

| Organic Cotton | GOTS / OCS Standards | Validates the absence of chemical sizing |

| Supima | DNA Traceability | Confirms ELS fiber strength |

Practical Quality Assurance for High-Volume Sourcing

Maintaining consistency across batches requires an integrated approach to quality control and performance. Buyers should mandate 'Golden Sample' retention, where an approved fabric swatch is kept at the factory and at the buying office for direct comparison during final random inspections. Additionally, on-site audits should verify the use of electronic yarn clearers and tension controls on the looms to prevent 'Pick-to-Pick' variation.

Expert Insight: If a supplier offers a 1000 TC sheet at a price comparable to a 300 TC sheet, it is technically certain that they are using multi-ply yarns made from short-staple fibers. Such products will likely fail pilling and abrasion tests (ASTM D4970) within the first few months of use.

Ready to secure your product quality before shipment?

As your third-party inspection, testing & certification partner in China, TradeAider supports brands and sourcing teams across the entire production process, helping you identify quality risks early, ensure compliance, and strengthen your team’s capabilities before shipment.

Book an Inspection or Testing Service with TradeAider today, or for tailored solutions and expert guidance, contact us at services@tradeaider.com or submit the request form on the right. →

Frequently Asked Questions (FAQ)

What is the maximum realistic thread count?

In a single-ply construction using ELS cotton, the maximum realistic thread count is approximately 500 to 600. Beyond this point, the yarns would have to be so thin that the fabric becomes structurally weak. Any claim above 800 almost certainly involves multi-ply yarns or counting individual strands within a thread.

Is thread count relevant for linen or silk bedding?

No. Thread count is specifically a metric for woven cotton. For linen, quality is measured by weight (GSM). For silk, the technical metric is 'Momme' (mm), which measures the weight of the silk substrate by volume.

Why do high thread count sheets feel stiff sometimes?

Stiffness can be caused by two technical factors: high yarn density restricting fiber movement, or the application of excessive chemical 'sizing' (starch or silicone) during the finishing process to artificially increase weight and luster.

Can a lab test detect if a sheet is actually 100% Egyptian Cotton?

Yes, through a combination of microscopy (analyzing fiber diameter and staple length) and DNA genotyping. Authentic Egyptian cotton has a specific genomic signature that distinguishes it from upland cotton grown elsewhere.

What is the best thread count for hot sleepers?

Technically, a Percale weave with a moderate thread count of 200 to 300 is best. The one-over-one-under structure is more porous, allowing for significantly higher breathability and thermal regulation compared to a dense 600 TC Sateen weave.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.