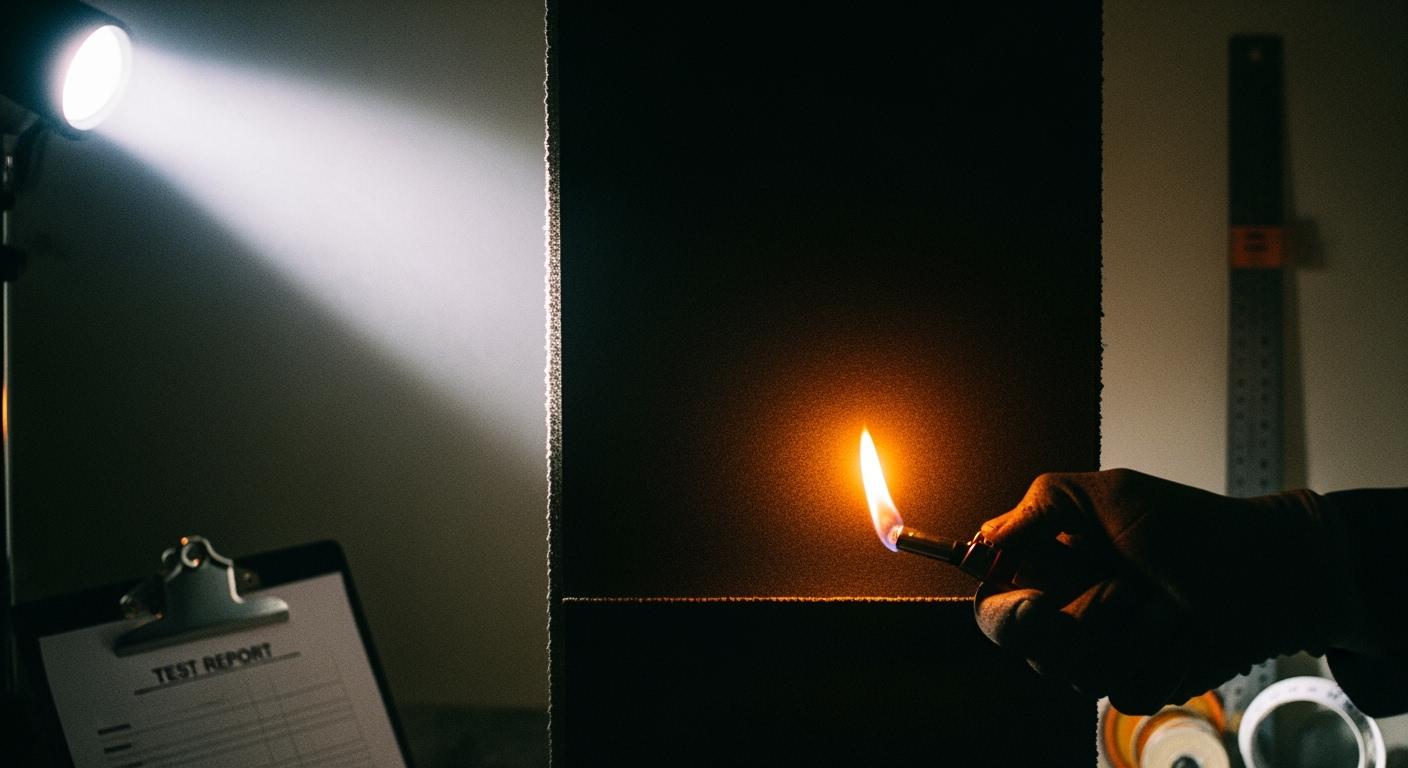

In the technical sector of Softline Products, blackout fabrics represent a pinnacle of light-attenuating engineering. These materials are utilized across residential, hospitality, and healthcare sectors to provide absolute darkness, thermal insulation, and acoustic damping. However, the operational reliability of these opaque textile substrates is governed by rigorous metrological validation and stringent fire safety protocols. A failure in light blockage or flammability compliance can lead to significant retail rejections or, more critically, catastrophic fire hazards in public venues. Understanding the laboratory protocols for opacity measurement and the chemistry behind flame retardancy is essential for manufacturers seeking compliance with international standards such as NFPA 701 and ISO 14501.

Key Takeaways

- Opacity levels are quantified by light transmission percentages, with 'True Blackout' requiring ≤ 0.1% transmittance.

- Flammability compliance is market-specific: NFPA 701 dominates the US market, while BS 5867 and EN 13773 are critical in Europe.

- Metrological opacity testing utilizes a high-intensity black chamber and lux meters to eliminate ambient light interference.

- Coating integrity is verified through ASTM D3359 'Cross-Hatch' adhesion tests to prevent delamination over the product lifecycle.

- Professional quality assurance audits are mandatory for verifying Inherently Flame Retardant (IFR) claims against cheaper chemical treatments.

- UV protection factors must be validated to ensure that solar radiation does not degrade the internal polymer coating layers.

The Engineering of Opacity: 3-Pass vs. 4-Pass Coatings

Blackout performance is achieved through either high-density weaving or the application of specialized polymer coatings. The most prevalent industrial method involves the 'Pass' system. Each pass adds a layer of acrylic or silicone coating to the back of the base fabric. Understanding this structure is vital for quality inspections during the manufacturing phase.

- 1-Pass: Known as 'Dim-out.' Provides thermal insulation but allows significant light filtration.

- 3-Pass: The industrial standard for blackout. It consists of a white layer (visual finish), a black layer (the light-blocking core), and a final white layer (to face the window and reflect heat).

- 4-Pass: Includes an additional 'Sizing' or 'UV-stabilization' layer to enhance coating adhesion and longevity against intense solar exposure.

| Performance Metric | Technical Objective | Industrial Benchmark |

|---|---|---|

| Light Transmission | Measure percentage of light through fabric | Class 4 (EN 14501) - 99.9% opaque |

| Thermal Resistance | Quantify solar heat gain coefficient | R-value > 1.5 for energy efficiency |

| Coating Adhesion | Test bond strength of polymer to fabric | ASTM D3359 Grade 5B (Zero peeling) |

| UV Transmittance | Evaluate UV-A and UV-B blocking | UPF 50+ (Blocks 98% of radiation) |

Metrological Testing for Light Blocking Performance

Laboratory validation of opacity requires the removal of human visual subjectivity. Technicians utilize an enclosed black chamber equipped with a standardized light source (Illuminant D65) and a high-resolution lux meter. According to metrological studies, the fabric must be tested across multiple spectral ranges to ensure that infra-red and ultra-violet rays are effectively attenuated.

The Shading Efficiency Scale (ISO 14501)

European markets utilize the EN 14501 standard to categorize shading devices. For a fabric to be marketed as "Total Blackout," it must reach Class 4. During standardized industrial testing, even microscopic "pinholes" in the coating will lead to a failure, as they allow light diffraction that compromises the privacy and comfort of the environment.

Technical Standard Alert: For fabrics intended for high-altitude or desert climates, testing must be performed after 100 hours of UV-exposure to ensure that the blackout coating does not become brittle and crack, which is the leading cause of "light leakage" in aged fabrics.

Flammability Standards and Fire Safety Chemistry

Fire safety is the most critical regulatory hurdle for blackout fabrics. Because curtains and drapes are suspended vertically, they can act as a primary fuel source, allowing flames to spread rapidly toward the ceiling. To prevent this, fabrics are either woven with Inherently Flame Retardant (IFR) yarns like Trevira CS or treated with Durable Flame Retardant (DFR) chemical salts.

Inherently Flame Retardant (IFR) vs. Treated (DFR)

IFR fabrics possess a modified molecular structure that is inherently non-combustible. This protection is permanent and will not wash out. DFR fabrics are treated with phosphorus or nitrogen-based chemicals that create an insulating 'char' when exposed to flame. During a factory audit, technical inspectors must verify chemical dip records and certificate validity to ensure the treatment hasn't been diluted.

| Standard | Test Methodology | Pass Criteria |

|---|---|---|

| NFPA 701 (Method 1) | Vertical burn of small samples | Afterflame < 2.0s; Mass loss < 40% |

| BS 5867 (Part 2) | Edge-ignition gas flame | Flame does not reach edges; zero flaming debris |

| DIN 4102-1 | B1 classification burner test | Self-extinguishing within a fixed time frame |

| UL 94 | Horizontal and vertical combustion | V-0 rating (Highest level of protection) |

Production Monitoring and In-Process Quality Control

Consistency in blackout production is achieved through real-time process monitoring. Automated Optical Inspection (AOI) systems are integrated into the coating lines to identify defects such as "doctor blade streaks" or "uneven tensioning" that could lead to dimensional instability. Effective production management requires that these digital logs be shared with the buyer to provide transparency into batch-level performance.

Coating Stability and Aging Tests

Beyond the initial pass, the coating must remain stable over years of opening and closing cycles. Standardized testing include:

- Flexing Endurance: Folding the fabric 10,000 times to check for coating delamination.

- Hydrostatic Aging: Exposure to 95% humidity to verify the polymer does not become 'sticky' or hydrolyze.

- Wash Fastness (ISO 105-C06): Ensuring that flame retardant properties are maintained after 5 to 50 industrial wash cycles.

Practical Guide for Professional Buyers and Importers

When sourcing blackout fabrics, a technical checklist is essential to mitigate risk. Organizations should prioritize documentation over visual samples. A technical report from an ISO 17025 accredited laboratory should include:

- Spectrophotometric Reflectance Data: Proving the actual light attenuation across the visible spectrum.

- Chemical Composition Analysis: Confirming the absence of restricted phthalates or lead-based pigments in the acrylic coating.

- Certificate of Origin for IFR Yarns: If IFR is claimed, the buyer must verify the yarn lot numbers against the fiber producer's records.

- Crocking and Rubbing Fastness: Ensuring the black internal coating layer does not rub off onto the outer fabric layer.

By prioritizing fabrics that have passed rigorous safety and performance testing, buyers can ensure they are delivering high-performance solutions that safeguard both consumer comfort and public safety.

Frequently Asked Questions (FAQ)

What is the difference between "Blackout" and "Room Darkening"?

Technically, "Blackout" refers to opaque textiles that block 99% to 100% of light (Class 4). "Room Darkening" or "Dim-out" fabrics block between 70% and 95% of light. In a laboratory test, blackout fabric will show zero lux transmission, while dim-out will show measurable light penetration.

Does flame retardancy have an expiration date?

For IFR (Inherently Flame Retardant) fabrics, the protection is permanent and lasts for the life of the fabric. For DFR (Treated) fabrics, the retardant chemicals can be washed away over time. Most DFR fabrics are rated for a specific number of washes (e.g., 5 or 20) before needing re-treatment.

Can I wash blackout curtains in a domestic machine?

Most coated blackout fabrics should not be machine washed, as the mechanical agitation can cause the polymer layers to peel (delamination). Technical specifications usually recommend "Dry Clean Only" or gentle spot cleaning to preserve the coating integrity.

How can I verify a manufacturer's NFPA 701 claim?

A legitimate NFPA 701 claim must be supported by a lab report that includes the specimen's weight, char length, and afterflame time. The report should explicitly state whether it followed "Test Method 1" (for single-layer fabrics) or "Test Method 2" (for heavy, multi-layered drapes).

Are blackout fabrics acoustic isolators?

Yes, to an extent. Due to the high density and the polymer coating layers, blackout fabrics have a high Sound Absorption Coefficient (NRC). While they cannot block low-frequency noise like traffic, they are technically efficient at reducing high-frequency echo and reverberation in a room.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.