An aql inspection chart gives you a structured way to manage product quality during the inspection phase. You use this chart to select the right sample size and set clear limits for defects, which strengthens your quality control process. The aql chart allows you to categorize defects as critical, major, or minor, which recent studies show can reduce defect rates and improve product quality. Both manufacturers and buyers depend on this approach to make informed decisions and maintain high standards.

Key Takeaways

- An AQL inspection chart helps manage product quality by setting clear limits for defects. Use it to categorize defects as critical, major, or minor.

- AQL stands for Acceptable Quality Level. It defines the maximum number of defects allowed in a sample before rejecting a batch.

- Follow a step-by-step process to use the AQL chart. This includes determining lot size, choosing inspection levels, and setting acceptance criteria.

- Always reject batches with critical defects. Major and minor defects have specific limits, but critical defects require immediate action.

- Use AQL sampling for cost-effective and efficient inspections. It saves time and money compared to inspecting every single unit.

AQL Inspection Chart Basics

What Is AQL?

You use AQL, or Acceptable Quality Level, as a statistical measure in quality control. It defines the maximum number of defective items you can accept in a sample before rejecting a batch. This approach recognizes that zero defects are often unrealistic, especially outside high-risk industries. AQL gives you flexibility to set quality standards that fit your product and industry.

Tip: AQL is not a fixed number. You can adjust it based on your product’s risk level and customer expectations.

Here is a quick overview:AQL,a statistical measure used in quality control to determine the maximum number of defective items acceptable in a sample. It is expressed as a percentage of defects per specified units, typically per one hundred.

Purpose of the AQL Inspection Chart

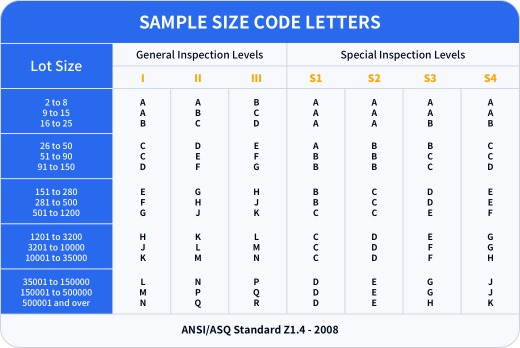

The aql inspection chart helps you apply aql sampling in a consistent and objective way. You use the chart to select the right sample size and inspection level for your batch. The chart links your lot size with a code letter, which then tells you how many units to inspect. This process ensures you follow international standards, such as ISO 2859-1 or ANSI-ASQ Z.14, which are both widely used in global trade. By using the aql chart, you can tailor your inspection to the criticality of your product and industry requirements.

Key Elements of the Chart

When you look at an aql inspection chart, you will see several key elements:

| Element | Function |

|---|---|

| Sample Size Code Letters | Links lot size with inspection levels. |

| Sample Sizes | Indicates how many units to check from a batch. |

| Acceptance and Rejection Numbers | Sets the threshold for passing or failing a batch based on defect counts. |

| Categories of Defects | Classifies defects into critical, major, and minor, ensuring appropriate responses to severity. |

| Sampling Methods | Various methods (single, double, sequential, multiple, skip lot) to apply aql sampling in practice. |

You use these elements to determine the sample size, the number of defects allowed, and the method of inspection. For example, if you have a batch that matches code letter G and an aql index of 2.5%, you might inspect 32 units and accept up to two defects. The aql tables make this process straightforward and repeatable, helping you maintain consistent quality standards.

Defect Types and Acceptable Quality Level

Critical, Major, and Minor Defects

You need to classify defects during an aql inspection to ensure consistent quality. Industry standards divide defects into three categories: critical, major, and minor. Each type affects your decision to accept or reject a batch. The table below shows how you can identify and respond to each defect type:

| Defect Type | Definition | Example |

|---|---|---|

| Critical | A defect that could cause injury or death to the consumer. | A wooden picture frame with splinters or a phone with an overheating battery. |

| Major | A defect that makes the product unsaleable or likely to be returned. | A monitor with a scratch on the front of the screen or a stapler that is the wrong color. |

| Minor | A defect that slightly deviates from specifications but is still saleable. | A monitor with a scratch on the back or a stapler that is a slightly different shade of blue. |

You should pay close attention to critical defects. These pose safety risks and require immediate action. Major defects impact usability and customer satisfaction. Minor defects may not affect function but can influence your brand reputation.

Note: Studies show that defect rates in consumer goods manufacturing can vary. For example, daily defective garment rates average 4%, but can reach up to 8.5% depending on quality control effectiveness.

Setting the Acceptable Quality Level

You set the acceptable quality level based on several factors. These include your product requirements, industry standards, and the quality control measures you use. The table below outlines what you should consider:

| Factor | Description |

|---|---|

| Quality Control Measures | Ensures that products meet specific specifications agreed upon by manufacturers and customers. |

| Industry Standards | Sets benchmarks for acceptable quality levels across different sectors. |

| Product Requirements | Specific needs of the product, such as safety for medical equipment, dictate lower aql levels. |

You must choose an aql value that matches your risk tolerance and customer expectations. For high-risk products, you select a lower aql to minimize defects. For less critical items, you may accept a higher aql.

Understanding Acceptance Quality Limit

You use the acceptance quality limit to decide if a batch passes or fails inspection. International standards organizations recommend a step-by-step approach:

| Step | Description |

|---|---|

| 1 | Determine Lot Size: Count total units in the batch. |

| 2 | Choose Inspection Level: General Level II balances inspection effort with confidence level. |

| 3 | Set aql Levels: Establish thresholds for critical, significant, and minor defects. |

| 4 | Consult aql Tables: Use ANSI/ASQ Z1.4 or ISO 2859-1 charts to find sample size code letter. |

| 5 | Determine Sample Size: Based on the code letter and aql level, locate the maximum allowable defects. |

You follow these steps to ensure your inspection process meets global standards. The acceptable quality limit helps you maintain consistency and transparency in your quality control system.

Using the AQL Inspection Chart

Choosing Sample Size and Inspection Level

You start the aql sampling process by selecting the right sample size and inspection level. The aql inspection chart guides you through this step. You need to consider your product's risk profile, customer requirements, and industry standards. The process involves several steps:

1. Choose the appropriate inspection level. General Level II is common for most consumer products, while Special Levels suit destructive or costly tests.

2. Locate your lot size in the aql tables. Find the row that matches your batch quantity.

3. Find the sample size code letter. Cross-reference your inspection level and lot size in Table 1.

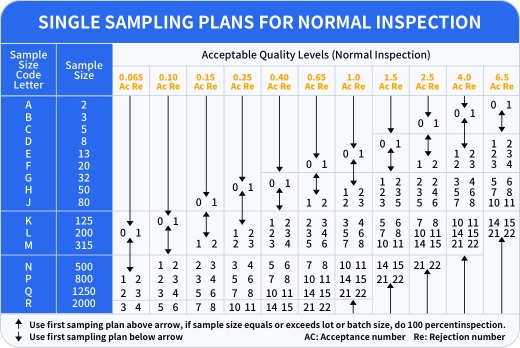

4. Determine the sample size and acceptance limits. Use the code letter in Table 2 to see how many units to inspect and the maximum number of defects allowed.

5. Conduct the inspection. Select the sample and check each unit for defects.

6. Make the decision. Compare the defect count to the acceptance limits to decide if you accept or reject the batch.

Tip: General Inspection Levels help you balance confidence and efficiency. Special Levels work best for tests that damage products or require fewer samples.

Here is a quick reference for the most commonly used aql tables:

| Table Number | Description |

|---|---|

| Table 1 | Sample Size Code Letters |

| Table 2 | Single Sampling Plans for Normal Inspection |

Determining Acceptance and Rejection Criteria

You use the aql chart to set clear criteria for acceptance or rejection. The chart divides defects into critical, major, and minor categories. Each category has its own acceptable quality level and threshold. You must reject any batch with critical defects, even if only one is found. Major and minor defects have specific limits based on the aql sampling plan.

| Type of Defect | Definition | AQL Threshold | Examples |

|---|---|---|---|

| Critical Defects | Serious issues that pose safety risks or make the product unusable. | 0.0 | Sharp metal fragments, missing safety labels |

| Major Defects | Defects that affect product function or appearance. | 2.5% | Misaligned seams, non-functional zippers |

| Minor Defects | Small cosmetic imperfections that do not affect usability or performance. | 4.0% | Slight smudging, tiny air bubbles |

You document every defect found during aql inspection. You record the type, location, and severity. You communicate these findings to the factory for corrective action. You also notify your client and recommend the best course of action. If necessary, you arrange a meeting with the factory to resolve issues and ensure accountability.

Interpreting AQL Results

You interpret aql inspection results by comparing the number of defects found to the acceptance quality limit. If the defect count stays within the acceptable quality level, you accept the batch. If it exceeds the limit, you reject it. You must pay special attention to critical defects, as even one will lead to automatic rejection.

You often use general inspection levels for most products. Special inspection levels apply when you need smaller sample sizes, such as for destructive tests. You may collaborate with third-party inspection companies to determine the best approach for special cases.

Practical Example

Suppose you have a lot size of 7,000 units and select General Inspection Level II. The aql chart shows code letter 'L', which means you inspect 200 units. The acceptance quality limit allows up to 10 major defects and up to 14 minor defects. If you find 8 major defects and 12 minor defects, you accept the batch. If you find 11 major defects, you reject it. If you find one critical defect, you must reject the entire batch.

Note: The aql selection process helps you maintain consistent quality standards and ensures transparency in your inspection decisions.

You use aql sampling to make informed decisions about product quality. The aql inspection chart provides a reliable framework for setting limits and interpreting results. You can confidently accept or reject batches based on objective criteria, protecting your interests and those of your customers.

Common AQL Questions and Misconceptions

Why Not 100% Inspection?

You might wonder why manufacturers do not inspect every single unit in all batches. In reality, aql sampling offers several advantages over 100% inspection. Industry reports highlight three main reasons:

| Reason for AQL Sampling | Explanation |

|---|---|

| Cost Efficiency | The cost of 100% inspection would outweigh the value of the product. |

| Time-Saving Benefits | AQL sampling allows for quicker inspections, which is crucial for large production volumes. |

| Acceptable Minor Defects | Some minor defects are tolerable and do not impact functionality or customer satisfaction. |

When you compare the two methods in apparel manufacturing, aql sampling proves less costly and less time-consuming. 100% inspection, while thorough, often takes much longer and increases costs, especially for large batches.

What If a Batch Fails AQL?

If you find that a batch does not meet the acceptance quality limit, you must take action. Manufacturers usually follow these steps:

- Listen to the factory’s concerns to identify misunderstandings or real issues.

- Offer a path forward, which may include:

a. Rework of defective goods followed by re-inspection.

b. Partial shipment approval for units that passed.

c. Concession decision for minor defects accepted in writing.

- Escalate the issue only if necessary, involving senior management or third-party mediation as a last resort.

You should never accept batches that exceed the acceptable quality limit. If you reject a batch, you protect your customers and maintain your quality standards.

Best Practices for AQL Inspections

To get the most from aql sampling and quality inspections, you should follow these best practices:

1. Select a product sample using aql tables and appropriate sampling methods.

2. Review specifications and use a checklist for efficiency.

3. Conduct visual inspections of both the product and packaging.

4. Perform physical testing on-site, tailored to the product type.

5. Document findings in a report, including photos and videos as evidence.

Misconceptions about aql can undermine your quality control program. Some new professionals believe limiting quality is the same as overall quality assurance, but limiting quality only refers to the threshold of defects allowed. Others think you can accept a lot even if it exceeds the acceptance quality limit, but you must reject such batches. These misunderstandings can lead to accepting defective products or rejecting acceptable ones, which affects your supplier relationships and the reliability of your quality assessments.

You now understand that an aql inspection chart gives you a practical way to manage product quality. By using this tool, you set clear standards for critical, major, and minor defects. You and your suppliers can agree on acceptable limits, which helps ensure product safety and customer satisfaction. Applying these principles in your inspections leads to better quality control and more reliable results.

FAQ

What does AQL stand for?

AQL stands for Acceptable Quality Level. You use it to set the maximum number of defects allowed in a sample before you reject a batch during inspection.

How do you choose the right AQL level?

You select the AQL level based on your product's risk, customer expectations, and industry standards. Lower AQL values mean stricter quality requirements.

Can you use AQL for any product type?

You can apply AQL sampling to most products, including electronics, textiles, and consumer goods. You should always adjust the AQL level to match your product’s safety and quality needs.

What happens if you find more defects than allowed?

If you find defects above the AQL threshold, you must reject the batch. You can request rework, re-inspection, or negotiate with your supplier for corrective action.

Is AQL inspection required by law?

Most countries do not require AQL inspection by law. However, you may need to follow AQL standards to meet customer contracts or industry regulations.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.