Quality control is key to making safe and reliable electronics. As technology gets better, people expect stronger and faster devices. Buyers want gadgets that work well and last a long time. In 2025, quality control in electronics becomes even more important. Companies must follow tougher rules and keep up with quick changes. By focusing on quality control, you can make sure your products meet these demands and keep customers happy.

Key Takeaways

• Quality control makes sure electronics are safe and work well. Find problems early to save money and protect your brand.

• Check and test products often during production. This keeps quality high and makes sure all products are the same.

• Use smart tools like AI and IoT to improve quality checks. These tools find problems fast and make production smoother.

• Work closely with suppliers by setting clear quality rules. Regular checks and talks help you get good materials.

• Learn about new ideas like blockchain and quantum computing. These can make quality checks clearer and faster.

Understanding Quality Control in Electronics

Definition and Scope

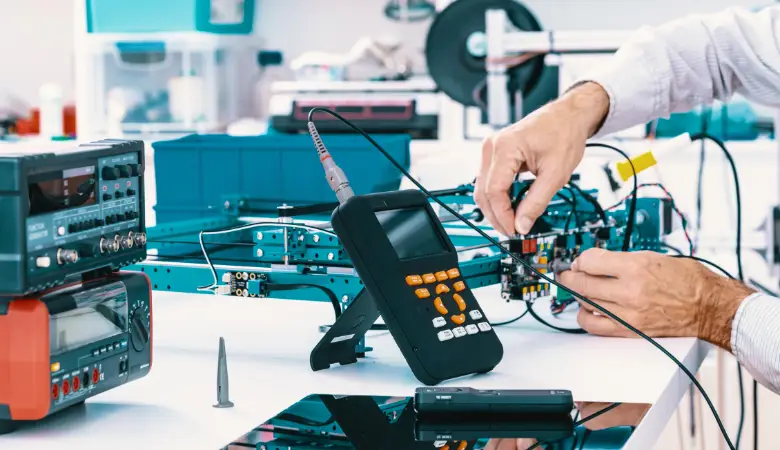

Quality control in electronics makes sure products meet set standards. It checks every step, from materials to the final product. Parts are checked, processes watched, and devices tested to ensure they work.

Quality control is more than just looking at physical parts. It also tests software, checks the environment, and follows rules. For example, you might test if a circuit board works in heat or if a device is safe to use. Doing this lowers risks and makes products more reliable.

Tip: Think of quality control like a safety net. It finds mistakes early, saving money and protecting your brand.

Key Objectives in Electronics Manufacturing

Quality control in electronics has three main goals: performance, safety, and consistency. First, it ensures devices work as they should. This includes testing battery life, speed, and connections.

Second, safety is very important. Products are checked for problems that could hurt users. For example, you might test for overheating or electrical issues.

Third, consistency is key. Customers want every product to be equally good. This is done by using the same processes and good materials.

To reach these goals, you must act early. Regular checks, better testing, and following rules help keep quality high.

Benefits of Quality Control in Electronics

Ensuring Safety and Reliability

You want your electronics to be safe and work well. Quality control helps by finding problems early. For example, testing batteries stops overheating issues. Regular checks make sure devices follow safety rules, keeping users safe from harm.

Reliable products do what they're supposed to do. This makes people trust your brand. A dependable device keeps customers happy and avoids expensive recalls. By focusing on safety and reliability, you make products people can count on.

Reducing Costs and Waste

Quality control saves money by cutting down on waste. Finding problems early means fewer bad products leave the factory. This reduces returns and repairs, which cost a lot. For example, checking materials ensures only good parts are used.

Good quality control also saves resources. Fewer failed products mean less energy and materials are wasted. This lowers costs and helps the planet. By wasting less, you save money and support the environment.

Building Brand Trust and Customer Loyalty

People stick with brands they trust. Quality control helps you earn trust by making great products. When customers know your devices are safe, they'll buy from you again.

A good reputation brings new customers too. Happy customers tell friends about your brand. By keeping high standards, you gain loyal buyers who spread the word. Loyal customers help your business grow over time.

Key Methods for Quality Control in Electronics

Incoming Material Inspections

Good electronics need dependable materials. Checking incoming parts ensures they meet your standards. For example, you can test how well wires carry electricity. You might also measure how thick circuit boards are. These checks catch bad parts early, stopping problems later.

To make this faster, use tools like AOI machines. These machines scan parts for mistakes quickly. They save time and reduce human errors. By checking materials first, you build a strong base for production.

Tip: Use a checklist for inspections. It keeps things consistent and helps your team follow the same quality rules every time.

Process Monitoring and In-Process Inspections

Watching the production process is just as important as checking parts. You need to check each step to keep things running smoothly. For example, you can measure soldering heat or check if assembly steps are correct.

In-process checks help find problems early. Use cameras and sensors to watch key steps in real time. If something goes wrong, you can fix it right away. This avoids expensive fixes later.

Regular monitoring also keeps products consistent. Watching closely ensures every item meets the same high standards.

Functional and Environmental Testing

After building the product, test how it works. Functional testing checks if the device does its job. For example, you might test a phone's screen or a laptop's battery.

Environmental testing is different. It mimics real-world conditions like heat, cold, or moisture. These tests make sure the product works in tough situations.

By doing both tests, you create reliable electronics. This step is key to keeping customers happy and trusting your brand.

Standards and Certifications (e.g., ISO 9001, IPC Standards)

Standards and certifications are important for making good electronics. They give clear rules for building, testing, and keeping products safe. By following these rules, you can make devices that customers trust and meet legal requirements.

Why Standards Matter

Standards help keep production consistent. They make sure all products are equally good. For example, ISO 9001 focuses on managing quality. It helps improve processes and meet customer needs.

Certifications also build trust with buyers. Certified products show they are safe and work well. This trust makes customers stick with your brand and buy again.

Key Certifications in Electronics

Here are some key certifications to know:

• ISO 9001: This standard improves processes, reduces mistakes, and meets customer needs.

• IPC Standards: These cover electronics production. For example, IPC-A-610 sets rules for electronic assemblies.

• RoHS Compliance: This ensures products don't have harmful materials. It helps meet environmental laws.

Tip: Use a checklist to track certifications. It keeps you organized and ensures compliance.

How to Implement Standards

Train your team to understand these rules. Use tools like software to check compliance. Regular audits help find problems and improve processes.

By using standards, your products meet global rules. This boosts quality and builds a strong reputation in the market.

Challenges in Implementing Quality Control in Electronics

Balancing Costs and Quality

Keeping costs low while ensuring quality is hard in electronics. Good materials and advanced tests often cost a lot. Saving money by skipping steps can make products fail. This hurts your reputation and loses customer trust. But spending too much on quality can reduce profits.

To manage this, focus on working smarter. Use machines to check parts faster and with fewer mistakes. Test the most important parts that affect safety and performance. By improving your process, you can keep quality high without spending too much.

Tip: Watch your quality control spending often. This helps you find ways to save money while keeping products reliable.

Managing Supply Chain Variability

Supply chains can be unpredictable and cause problems in production. Materials from suppliers might not always be the same quality. Late deliveries can mess up schedules and lead to rushed work. This increases the chance of errors.

To handle this, set clear rules for suppliers. Tell them exactly what quality and delivery times you need. Work closely with trusted suppliers and check how they perform. Have more than one supplier to avoid big risks if one fails.

Use technology to track materials better. Tools like blockchain show where materials come from and when they arrive. This keeps your supply chain steady and clear.

Note: A well-organized supply chain reduces surprises and keeps production smooth.

Adapting to Rapid Technological Changes

Technology changes fast, and it's tough to keep up. New designs and materials need updated testing methods. If you don't adjust, your quality checks might miss problems. This can lead to faulty products.

Stay prepared by investing in learning and research. Teach your team about new technologies and how they affect quality checks. Use smart tools like AI to spot issues before they happen.

Callout: Learning all the time helps you handle new tech. Train your team to face these challenges confidently.

By solving these problems, you can improve Quality Control in Electronics and make products customers trust.

Best Practices for Quality Control in Electronics in 2025

Continuous Monitoring and Real-Time Data Analysis

Watching production all the time helps catch problems early. Using real-time data lets you fix issues fast. Sensors and software tools check each step and collect data quickly. This data shows mistakes and patterns.

For example, IoT devices can track soldering heat or assembly speed. If a machine gets too hot, the system warns you right away. Fixing it quickly stops bad products and saves time.

Studying live data helps you make better choices. You can change processes to work faster and waste less. This improves product quality and saves resources.

Tip: Dashboards show live data clearly. They help you see trends and act fast.

Standardizing Supplier Quality Requirements

Suppliers affect how good your products are. Clear rules make sure you get good materials. Create a list of needs like strength, size, and eco-friendly compliance. Share this list with all suppliers.

Check suppliers often to ensure they follow your rules. Visit their sites and test their materials. If a supplier doesn't meet your needs, find another one to avoid problems.

Setting clear rules builds trust with suppliers. They know what you want and work harder to deliver. This keeps production steady and reduces surprises.

Callout: Good supplier relationships mean better materials and fewer production problems.

Investing in Workforce Training and Development

Your workers are key to keeping quality high. Training helps them learn new tools and methods. Teach them to use inspection tools, follow rules, and find defects.

Hold workshops to keep their skills updated. For example, train them to use AI tools for testing. Skilled workers spot problems faster and improve production.

Training also makes workers feel appreciated. They work harder when they know you care about their growth. A happy team helps keep quality high.

Note: Trained workers make fewer mistakes and focus on quality.

Using Advanced Technologies (e.g., AI, IoT, Machine Learning)

New technologies like AI, IoT, and Machine Learning are changing how we check quality in electronics. These tools find problems faster, work more efficiently, and reduce mistakes. By using them, you can stay competitive in the fast-moving electronics industry.

How AI Helps with Quality Control

AI systems process large amounts of data quickly. They spot patterns and warn about issues before they happen. For example, cameras with AI can check circuit boards for flaws instantly. These systems are quicker and more accurate than people.

Tip: Let AI handle repetitive tasks. This frees up your team to solve harder problems.

IoT for Watching in Real Time

IoT connects machines, sensors, and systems to share data. It gathers information from every production step. For instance, IoT sensors can monitor temperature and humidity in factories. If conditions become unsafe, the system sends an alert right away.

• How IoT Helps Quality Control:

Keeps an eye on production all the time.

Sends alerts if machines break down.

Tracks materials and parts better.

Callout:IoT catches problems early, saving time and reducing waste.

Machine Learning for Predicting Repairs

Machine Learning studies data to guess when machines might fail. It learns from past data and spots warning signs. For example, it can check vibrations in machines. If something seems off, it suggests fixing the machine before it breaks.

• Why Predicting Repairs is Important:

Stops machines from breaking suddenly.

Makes machines last longer.

Cuts repair costs and avoids delays.

Combining Tools for Best Results

Using AI, IoT, and Machine Learning together creates a strong quality control system. AI analyzes data, IoT collects it, and Machine Learning predicts problems. Together, they help you make smarter choices and improve product quality.

Note: Start with one technology first. Add more as your team gets used to them.

By using these advanced tools, you can improve quality checks and make reliable electronics that customers trust.

Emerging Trends in Quality Control in Electronics

AI and Machine Learning for Predictive Quality

AI and Machine Learning are changing how we check quality. These tools study lots of data to find problems early. For example, AI can watch machines and spot unusual patterns. If a machine acts strangely, you can fix it before it breaks.

Machine Learning goes further by learning from past mistakes. It gets smarter over time and predicts problems better. Imagine a system that warns you about a machine overheating or vibrating too much. Fixing it early avoids delays and keeps products consistent.

Tip: Begin with small tasks like finding defects. Add more uses as you see success.

Blockchain for Supply Chain Transparency

Blockchain helps make supply chains clear and trustworthy. It keeps secure records of every step, from materials to finished products. This lets you track where parts come from and if they meet your standards.

For example, you can check if a supplier follows your rules by looking at their blockchain data. If something goes wrong, you can trace the problem fast. This builds trust with customers and ensures you follow laws.

Blockchain also stops fake parts from entering your supply chain. Each part gets a special digital tag to prove it's real. This ensures only good materials are used in your products.

Callout: Using blockchain improves quality and makes your brand more reliable.

Quantum Computing and Its Potential Impact

Quantum Computing is new but could change quality control soon. It solves hard problems much faster than regular computers. This could help test designs and improve production steps.

For example, Quantum Computing might show how parts act in extreme heat or pressure. You could test ideas virtually before making them, saving time and money. It could also make predictions more accurate, finding issues earlier.

Though Quantum Computing isn't common yet, learning about it now helps you prepare. Using it early could give you an advantage in keeping high quality.

Note: Watch for updates on Quantum Computing. It might become very useful for quality control soon.

Quality control is very important in making electronics. It makes sure your products are safe, work well, and satisfy customers. Using smart tools like AI and IoT helps find mistakes faster and improves checks. Always improving your process keeps things running smoothly and products the same every time.

Tip: Learn about new ideas like blockchain and quantum computing. These could change how you check quality. Knowing about them helps you stay ahead and make great products.

Pay attention to quality control to gain trust, waste less, and grow your brand.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.