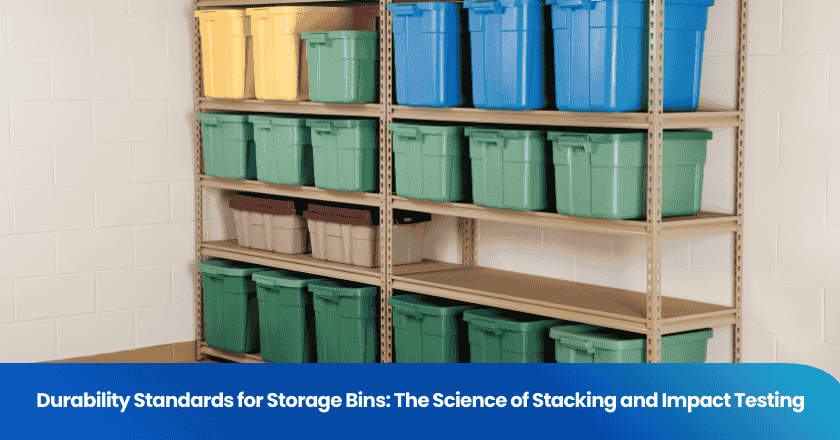

Mechanical testing is the cornerstone of reliability for Storage Bins and Organizers used in industrial, commercial, and residential environments. These containers are often subjected to extreme stresses, ranging from long-term vertical loads in a warehouse to accidental impacts during logistics. By utilizing rigorous methods such as compression analysis and drop impact resistance testing, manufacturers can identify structural vulnerabilities before products reach the market. These protocols form the foundation of quality control for hardline consumer goods, ensuring safety and protecting the financial investment of the end-user.

The Physics of Load Stacking and Compression

Load stacking is not merely about weight capacity; it is an engineering challenge involving static force and polymer physics. Compressive strength testing measures the maximum vertical force a container can withstand before structural failure or unacceptable deformation occurs. This is critical for high-density storage where bins are stacked ten or more units high.

Static vs. Dynamic Load Testing

Engineers distinguish between static loads (containers sitting in a warehouse) and dynamic loads (vibrations and shifts during transport). During a compression test, a hydraulic press applies force at a constant rate. For a product to pass, it must maintain its structural integrity without significant bowing of the sidewalls or collapse of the lid structure.

| Testing Parameter | Technical Objective | Real-World Application |

|---|---|---|

| Ultimate Compressive Load | Determine point of total collapse | Safety factor calculation for stacking limits |

| Creep Analysis | Measure deformation over 24-72 hours | Long-term structural stability in storage |

| Deflection at Peak | Measure sidewall bowing distance | Ensuring bins stay locked when stacked |

| Nesting Ratio Test | Measure empty stacking efficiency | Optimizing logistics and shipping costs |

Polymer Creep and Stacking Failure

A common cause of failure in plastic storage bins is "creep"—the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. Even if a bin survives an initial load, it may collapse three months later if the plastic "flows" under pressure. High-quality industrial storage solutions use ribbing designs and specific HDPE or PP blends to mitigate this effect.

Dimensional Integrity and Precision Molding

For storage bins to be effectively stackable, dimensional tolerance is non-negotiable. If a bin's footprint varies by even 0.05 inches, the interlocking mechanism may fail, leading to unstable stacks that pose a safety risk to workers. Manufacturers utilize coordinate measuring machines (CMM) to verify that every injection-molded unit meets technical specifications.

Engineering Focus: Shrinkage rates of polymers like Polypropylene (PP) can vary based on cooling speed. A robust factory audit must verify that the molding cycles are consistent to prevent warped bottoms or misaligned lids.

Drop Impact Resistance: Survival in the Supply Chain

Drop testing simulates the hazards of the modern supply chain. Whether a bin falls off a forklift or is dropped by an delivery driver, its ability to absorb energy without fracturing determines its value. Impact resistance is measured by the ability of the material to redistribute the energy of an impact throughout its structure.

ISTA 1A and ASTM D5276 Protocols

Industry-standard protocols require a specific sequence of drops to ensure all vulnerable points are tested. For instance, the ISTA 1A procedure typically involves a 10-drop sequence on a single unit:

- 1 Corner drop (most vulnerable point)

- 3 Edge drops (different orientations)

- 6 Face drops (all sides, top, and bottom)

The drop height is inversely proportional to the weight. A bin weighing under 21 lbs might be dropped from 30 inches, whereas a heavy industrial bin of 100 lbs might be tested at 12 inches. This reflects the reality that heavier objects are rarely lifted as high as lighter ones.

| Material Type | Impact Resistance Level | Common Use Case |

|---|---|---|

| Polypropylene (PP) | Moderate to High | General purpose residential bins |

| High-Density Polyethylene (HDPE) | Very High (even in cold) | Industrial crates, outdoor storage |

| Polycarbonate (PC) | Extreme (Transparent) | Heavy-duty clear organizers, military use |

| ABS Plastic | High Rigidity | Hard-shell tool organizers |

Environmental Stress Factors

Mechanical strength is not constant; it changes based on the environment. High-quality mechanical testing also accounts for temperature and chemical exposure.

- Thermal Cycling: Plastic becomes brittle in cold weather and soft in extreme heat. Bins intended for unheated warehouses must pass drop tests at sub-zero temperatures.

- UV Degradation: Exposure to sunlight breaks down polymer chains (photo-oxidation). Impact resistance can drop by 50% after a single season of outdoor use if UV stabilizers are not added to the resin.

- Chemical Resistance (ESCR): Environmental Stress Cracking Resistance tests determine if the bin will crack when it comes into contact with detergents, oils, or solvents while under stress.

Selecting the Right Storage Solution

When selecting bins for industrial or large-scale use, looking beyond the marketing labels is essential. Buyers should demand standardized inspection reports that detail the specific test results for compressive load and impact. A bin rated for 50 lbs of internal weight may fail if the lid is only rated for a 20 lb stack load.

Furthermore, consider the design features that improve durability without increasing weight. For example, a reinforced radius at the corners distributes stress more effectively than sharp 90-degree angles. Gusseted handles prevent the sides from cracking when the bin is carried at full capacity.

FAQ

What is the difference between a static load and a dynamic load?

A static load refers to a bin sitting still with weight on it, where the main concern is "creep" or slow deformation. A dynamic load occurs during movement, where vibration and sudden shocks (like a truck hitting a pothole) increase the effective weight of the stack significantly.

How does "Notched IZOD Impact" testing help in bin selection?

This is a material-level test that measures how much energy a plastic can absorb when it has a small notch (simulating a scratch or minor crack). Materials with high IZOD scores are much less likely to shatter if they get scuffed or damaged in a warehouse.

Can I use residential bins for industrial stacking?

Generally, no. Residential bins often lack the wall thickness and the structural ribbing required to handle the sustained vertical pressure of industrial racking. Failure to use properly tested bins can lead to workplace accidents and product damage.

Why do some bins crack in the winter?

Many plastics, particularly standard Polypropylene, reach their "Glass Transition Temperature" in cold weather, becoming extremely brittle. For cold-chain or outdoor use, bins made from "Impact Copolymer" or HDPE are required as they maintain flexibility at low temperatures.

What is the importance of a carton drop test for e-commerce?

E-commerce packaging faces more individual touches than traditional retail. A carton drop test ensures that the individual organizers inside a master carton won't arrive at the customer's door with cracked corners or shattered lids due to rough handling by couriers.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.