You play a key role in ensuring quality control in electronics manufacturing. Strong quality control helps you deliver reliable products, reduce waste, and keep customers happy. When you focus on quality at every step, you lower costs and prevent defects. Quality control builds trust in your processes and boosts your reputation for quality in a competitive market.

Why Quality Control in Electronics Manufacturing Matters

Product Reliability

You want your products to work every time your customers use them. Quality control in electronics manufacturing helps you achieve this goal. When you focus on quality, you reduce the risk of failures and increase reliability. Reliable products build trust with your customers. You can prevent defects from reaching the market by checking each step of the manufacturing process. This attention to detail ensures that your electronics perform as expected, even in tough conditions. Reliability also means fewer returns and repairs, which saves you time and money.

Cost and Efficiency

Quality control does more than just catch mistakes. It helps you save money and use your resources wisely. When you spot defects early, you avoid costly rework and scrap. You can also improve your manufacturing processes by studying where problems happen. This leads to better efficiency and less waste. Quality control in electronics manufacturing lets you use your materials and labor more effectively. You can lower the cost of manufacturing by reducing errors and improving workflow. Efficient production means you can deliver products faster and keep your business competitive.

Customer Satisfaction

Your customers expect high-quality electronics that last. Quality control in electronics manufacturing helps you meet these expectations. When you deliver reliable products, your customers feel confident in your brand. They are more likely to recommend your products to others. If you ignore quality, you risk sending out products with manufacturing defects. This can lead to complaints, returns, and lost sales. By focusing on quality, you show your customers that you care about their experience. Satisfied customers help your business grow and succeed.

Foundational Principles

DFM and DFA

You need to start every electronics project with strong design for manufacturing and design for assembly practices. DFM helps you create products that are easy to build. DFA focuses on making products simple to put together. When you use dfm, you follow clear guidelines that help you avoid mistakes during production. You look for ways to reduce the number of parts and choose materials that work well in your process. Dfa means you think about how each part fits together. You use design for manufacturing to make sure machines can handle your parts. You use design for assembly to make sure workers can put things together quickly. Dfm and dfa both help you lower costs and improve reliability. You should always review your designs with these guidelines in mind. Dfm and dfa make your products easier to test and repair, too. You can use checklists to make sure you follow all the design for manufacturing steps. Dfa helps you spot problems before they reach the factory. Dfm and dfa are key to building quality electronics.

DFR and DFT

You also need to focus on design for reliability and design for test. Design for reliability means you plan for your product to last. You use design for reliability to pick strong parts and test your designs in tough conditions. Dfm and dfa help you build the product, but design for reliability makes sure it works over time. You use guidelines to check for weak spots in your design. Design for test helps you add features that make testing easy. You use design for manufacturing and design for reliability together to make sure your product is strong and easy to check. Dfm, dfa, and design for reliability all work together to boost quality.

Product Class Selection

You must choose the right product class for your project. Each class has its own guidelines for dfm, dfa, and design for manufacturing. Some products need higher reliability, so you use stricter design for reliability rules. You follow the guidelines for your class to make sure you meet safety and quality goals. Dfm and dfa help you match your design to the right class. You use design for manufacturing and design for reliability to make sure your product meets customer needs.

PCB Quality Control Essentials

PCB Design Checks

You need to start every pcb project with careful design checks. These checks help you catch errors before you begin manufacturing. You should review the layout for clearances, trace widths, and component placement. A good layout prevents short circuits and signal interference. You must check that the printed circuit board meets all critical quality parameters. These parameters include hole sizes, pad shapes, and spacing. You should use design rule checks (DRC) to find mistakes in the layout. DRC tools highlight problems that could cause defects during manufacturing. You also need to verify that the layout supports the electrical performance you want. Signal integrity and power distribution play a big role in high-quality pcbs. You should always document your design checks. This record helps you improve quality control in future projects.

Tip: Use a checklist for every pcb design review. This habit ensures you do not miss any critical quality parameters.

Material Selection

You must choose the right materials for your pcb. The material affects the durability, performance, and reliability of the printed circuit board. You should look at the thermal, electrical, and mechanical properties of each material. For example, FR-4 is a common choice for many pcb applications. You may need special materials for high-frequency or high-temperature uses. The right material helps you meet critical quality parameters such as insulation resistance and thermal stability. You should also check that the material matches your manufacturing process. Some materials work better with certain soldering methods or assembly techniques. You need to confirm that the material supports the layout and the final product’s requirements. Good material selection leads to fewer defects and better quality control.

| Material Type | Key Properties | Typical Use Cases |

|---|---|---|

| FR-4 | Good insulation, cost | General electronics |

| Polyimide | High temp, flexible | Flexible printed circuit board |

| Rogers | Low loss, RF | High-frequency pcb |

SMT and THT Choices

You need to decide between surface-mount technology (SMT) and through-hole technology (THT) for your pcb assembly. SMT places components directly on the surface of the pcb. THT inserts component leads through holes in the printed circuit board. Your choice affects the layout, manufacturing speed, and critical quality parameters. SMT works well for small, high-density layouts. It allows you to place more components on both sides of the pcb. THT gives you strong mechanical bonds, which help in products that face stress or vibration. You should match the assembly method to your product’s needs and the required quality level. You must also consider how each method impacts quality control. SMT needs precise placement and soldering. THT requires careful hole alignment and solder fill. Both methods need inspection to meet critical quality parameters. You should use automated inspection tools to check for defects in both SMT and THT assemblies.

Note: Mixing SMT and THT on one pcb can help you balance cost, performance, and quality.

You can achieve high-quality pcbs by focusing on these essentials. Careful design checks, smart material selection, and the right assembly method help you meet all critical quality parameters. These steps form the foundation of strong quality control in pcb manufacturing.

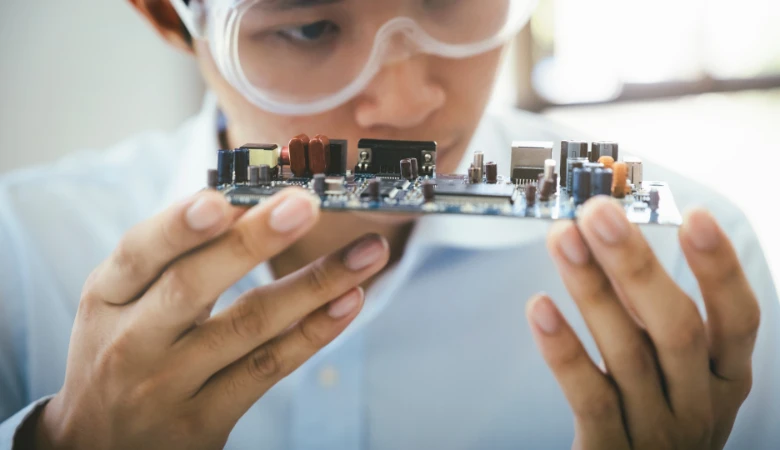

Testing and Inspection

You need strong testing and inspection processes to ensure your pcb meets high quality standards. These steps help you catch defects early and confirm that your electronics work as designed. You can use several methods to check your products. Each method supports quality control and helps you deliver reliable electronics.

In-Circuit Testing (ICT)

In-circuit testing checks the electrical performance of your pcb assemblies. You use this method to measure values like resistance, capacitance, and voltage at different points on the board. ICT helps you find problems such as short circuits, open circuits, and incorrect component values. You place test probes on specific points of the pcb to collect data. This process gives you fast feedback during production.

You can use ICT to:

• Detect assembly defects before final assembly.

• Verify that each component sits in the correct place.

• Confirm that solder joints work as expected.

ICT supports both testing and validation. You can use it to check every board or just a sample from each batch. This method helps you reduce rework and improve overall quality. You should include ICT in your quality control plan for complex pcb designs.

Tip: Design your pcb with test points to make ICT easier and more accurate.

Automated Optical Inspection (AOI)

Automated optical inspection uses cameras and software to check your pcb for visual defects. You can use AOI to inspect solder joints, component placement, and surface quality. The system compares each board to a reference image. It highlights differences that may signal defects.

AOI helps you:

• Catch missing or misaligned components.

• Spot solder bridges and poor connections.

• Identify surface flaws that affect reliability.

You can use AOI early in the production line. This step lets you fix problems before they reach later stages. AOI supports automated testing and speeds up the inspection process. You can rely on AOI for fast, repeatable results. This method improves quality and reduces human error.

| AOI Benefits | Description |

|---|---|

| Speed | Inspects many pcb quickly |

| Consistency | Delivers repeatable results |

| Early Defect Detection | Finds issues before final assembly |

Functional Testing

Functional testing checks if your pcb works as intended in real-world conditions. You connect the board to power and run it through its normal operations. This process helps you confirm that the product meets all design requirements.

You use functional testing to:

• Simulate how the pcb will perform in the final product.

• Test features like signal processing, communication, and power delivery.

• Validate that the board meets customer expectations.

Functional testing and validation go hand in hand. You can use this method to catch hidden defects that other tests might miss. You should include functional testing in your quality control plan for every new design. This step ensures that your electronics deliver the performance your customers expect.

Note: Always document your functional testing results. This record helps you track quality trends and improve future designs.

Diagnostic Tools

Diagnostic tools help you find and fix problems during pcb testing and validation. You can use oscilloscopes, logic analyzers, and multimeters to measure signals and voltages. These tools let you dig deeper into issues that automated testing might reveal.

You use diagnostic tools to:

• Pinpoint the source of defects.

• Analyze signal integrity and timing.

• Validate repairs and confirm that fixes work.

You should train your team to use diagnostic tools effectively. Skilled use of these tools supports quality control and helps you maintain high standards. Diagnostic tools play a key role in testing and validation, especially when you need to troubleshoot complex boards.

Callout: Combine automated testing with manual diagnostics for the best results. This approach gives you a complete view of your pcb quality.

You can achieve strong quality control by using a mix of in-circuit testing, AOI, functional testing, and diagnostic tools. These methods help you catch defects, validate your designs, and deliver reliable electronics. Testing and validation are essential steps in every successful pcb manufacturing process.

Process Control

Manufacturing Control Systems

You need strong manufacturing control systems to keep your pcb production on track. These systems help you monitor every step of the manufacturing process. You can use them to track materials, check machine settings, and record inspection results. When you follow clear guidelines, you improve quality and maximize compliance. Manufacturing control systems let you spot problems early. You can fix issues before they lead to defects. These systems also help you meet compliance rules for your pcb products. You should use manufacturing control systems to support dfm and dfa goals. This approach helps you keep your manufacturing process stable and reliable.

Process Standardization

Process standardization gives you a clear path to quality. You set up standard steps for each part of pcb manufacturing. When you use standard processes, you reduce mistakes and make training easier. You should write down your guidelines for each step. This helps everyone follow the same rules. Standardization supports dfm and dfa by making sure each pcb meets the same quality level. You can use checklists to track each step. This method helps you maximize compliance and meet quality control targets. Standard processes also make it easier to pass compliance audits.

Tip: Review your process guidelines often. Update them when you find better ways to improve quality or reduce defects.

Soldering Techniques

You must use the right soldering techniques to avoid soldering defects in pcb manufacturing. Good soldering keeps your connections strong and reliable. You should train your team to spot and fix soldering defects quickly. Use dfm and dfa guidelines to design boards that are easy to solder. This step helps you prevent common soldering defects like cold joints, bridges, and voids. You should inspect each pcb after soldering to check for quality issues. Good soldering supports compliance and helps you deliver high-quality products. When you follow design for manufacturing and process guidelines, you lower the risk of defects and improve overall quality.

| Soldering Defect | Cause | Prevention Tip |

|---|---|---|

| Cold Joint | Low heat or poor contact | Use correct temperature |

| Solder Bridge | Excess solder | Control solder amount |

| Voids | Trapped air | Use proper soldering method |

You can achieve strong quality control in pcb manufacturing by focusing on these process control steps. Use manufacturing control systems, standardize your processes, and apply the best soldering techniques to maximize compliance and deliver reliable products.

Continuous Improvement

You need to focus on continuous improvement to keep your electronics manufacturing process strong. This approach helps you find new ways to boost quality and reduce defects. You can use proven methodologies to guide your efforts and make sure every step leads to better results.

Lean Six Sigma

Lean Six Sigma gives you powerful methodologies for improvement. You use these tools to remove waste and cut down on errors. Lean focuses on streamlining your process. Six Sigma helps you control variation and improve quality. You can start by mapping your workflow and finding steps that slow you down. Use data to spot where defects happen most often. Lean Six Sigma methodologies help you set clear goals and measure your progress. Many factories have used these methodologies to cut defects by half and raise quality scores.

Tip: Start small. Pick one process for improvement and apply Lean Six Sigma steps. Track your results and share them with your team.

Feedback Loops

You need strong feedback loops to support continuous improvement. Feedback helps you catch problems early and learn from mistakes. Set up regular meetings to review quality data. Ask your team to share ideas for improvement. Use feedback to adjust your process and test new methodologies. For example, you might notice a spike in defects after a process change. Quick feedback lets you fix the issue before it spreads. Feedback loops keep your improvement efforts on track.

• Collect data after each production run.

• Review results with your team.

• Make small changes and measure the impact.

Training and Quality Culture

You build a culture of quality by training your team and encouraging improvement. Teach your staff about key methodologies and why they matter. Hold workshops on Lean Six Sigma and other improvement tools. Reward team members who suggest ways to boost quality. When everyone values improvement, you see fewer defects and better results. Real-world examples show that factories with strong training programs see steady gains in quality and efficiency.

Note: Continuous improvement works best when everyone feels responsible for quality. Keep training fresh and involve your team in every step.

Common Mistakes

Skipping Early Quality Planning

You might feel tempted to jump straight into production, but skipping early quality planning can lead to big problems. When you do not plan for quality from the start, you risk missing important steps in your pcb process. Early planning helps you set clear goals for quality and avoid costly mistakes later. You should always review your pcb design and process before you begin. This step helps you catch issues that could affect the final product.

Tip: Create a checklist for early quality planning. This habit keeps your pcb projects on track and supports strong results.

Inadequate Training

If your team does not receive enough training, you will see more errors in your pcb assembly. Training gives your workers the skills they need to spot defects and follow best practices. You should hold regular training sessions to keep everyone up to date. Well-trained staff can handle new equipment and changing pcb requirements. This focus on learning helps you maintain high quality in every project.

Ignoring Process Variability

You need to watch for changes in your pcb manufacturing process. Ignoring process variability can lead to defects and lower quality. Small shifts in temperature, humidity, or machine settings can affect your pcb output. You should track these factors and adjust your process when needed. Use data to find patterns and fix problems early.

| Process Factor | Possible Impact on PCB |

|---|---|

| Temperature | Soldering defects |

| Humidity | Material issues |

| Machine setup | Misaligned components |

Overlooking Test Data

You collect a lot of test data during pcb production, but you must use it to improve quality. If you overlook this data, you miss chances to spot trends and prevent future defects. Review your test results after each batch. Share findings with your team and make changes based on what you learn. This habit helps you deliver better pcb products and keeps your quality high.

Implementation Strategies

Risk-Based Approach

You can improve your manufacturing process by using a risk-based approach. Start by identifying the steps in your process that have the highest chance of causing defects. Focus your quality checks and testing on these areas. This method helps you use your resources wisely. You can set up extra inspections or controls where you see the most risk. Always review your process data to spot new risks. This approach supports compliance because you address problems before they lead to bigger issues. Use your quality management systems to track risks and actions.

Tip: Make a simple chart to rank each step by risk. Update it after every major change in your manufacturing process.

Cross-Functional Teams

You need cross-functional teams to keep your quality high. Bring together people from engineering, production, and compliance. Each team member sees the process from a different angle. This teamwork helps you find problems faster and fix them before they affect your products. Hold regular meetings to share updates and review testing results. When everyone works together, you build a strong quality culture. Cross-functional teams also help you meet compliance goals because they catch issues early.

• Assign clear roles to each team member.

• Share quality and compliance data at every meeting.

• Encourage open communication about manufacturing challenges.

Automated Inspection Systems

Automated inspection systems help you check every product quickly and accurately. These systems use cameras and sensors to find defects that people might miss. You can use them for visual checks, measurements, and even some types of testing. Automated systems support compliance by keeping records of every inspection. They also help you keep up with fast manufacturing lines. When you add automation, you reduce errors and improve quality.

| Benefit | How It Helps Manufacturing |

|---|---|

| Faster inspections | Keeps up with production speed |

| Better compliance | Stores inspection records |

| Higher quality | Finds small defects early |

Note: Start by automating the inspection steps that take the most time or cause the most errors.

You can build a strong quality program by using risk-based controls, cross-functional teams, and automated inspection systems. These strategies help you meet compliance, improve testing, and keep your manufacturing process efficient.

You can achieve high-quality output in electronics manufacturing by following essential quality control practices. Focus on foundational principles first, then add advanced strategies as you grow. These steps help you boost reliability and reduce defects. Review your current process and look for areas that need improvement. Take action now to build a stronger quality culture and deliver better products to your customers.

Smart Sourcing & Quality Assurance Content Team

Article by Smart Sourcing & Quality Assurance Content Team

The Smart Sourcing & Quality Assurance Content Team is dedicated to delivering high-quality, easy-to-understand information that empowers our audience to navigate the complexities of global sourcing and quality assurance. Our team of writers has extensive experience in creating content across various fields, including procurement, supply chain management, quality assurance, market trends, and industry best practices. We specialize in sectors such as apparel, textiles, and consumer goods, providing targeted insights to help businesses in these industries optimize their sourcing strategies, ensure product quality, and maintain a competitive edge in the market.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.