You rely on an acceptable quality level table to make clear, unbiased choices during inspection. This tool helps you compare product batches against a set acceptable quality level, ensuring your decisions remain consistent. When you use an aql table, you measure the number of defects and decide whether a batch is acceptable. The aql method guides you in setting standards and supports every inspection with objective data.

Key Takeaways

- Use AQL tables to make unbiased inspection decisions. They help you determine if a product batch meets quality standards.

- Set clear acceptance quality limits to define the maximum number of defects allowed. This ensures consistent quality control.

- Select the appropriate inspection level based on product risk and budget. This choice impacts sample size and defect limits.

- Always confirm lot size and sample size before inspections. This step supports reliable quality control and accurate results.

- Document your AQL values and inspection levels. This practice ensures transparency and consistency in your quality assurance process.

What Is an Acceptable Quality Level Table?

Definition of Acceptable Quality Level

You need a clear standard when you inspect products. The acceptable quality level defines the maximum number of defects you can tolerate in a batch before you reject it. This value sets the threshold for quality. You use the aql to measure whether a shipment meets your requirements. The aql expresses quality as a percentage or number of defective units allowed in a sample. For example, if you set the aql at 1%, you accept up to one defective item per hundred inspected. This approach helps you balance strict quality control with practical production realities.

Tip: The aql gives you a practical way to decide if a batch is acceptable without inspecting every single item.

You rely on aql tables to apply these limits consistently. These tables show you how many samples to inspect and how many defects you can allow. You use the acceptance quality limit to guide your decisions. The aql limits help you maintain quality while keeping inspection efficient.

Purpose of AQL Table

The aql table serves as your roadmap during inspection. You use it to select the right sample size and set defect limits for each batch. The table standardizes your process, so you make objective decisions every time. You avoid guesswork and rely on clear criteria.

Here is how an aql table supports your inspection process:

| Step | What You Do | Why It Matters |

|---|---|---|

| Determine lot size | Count total units in the batch | Ensures correct sample selection |

| Choose inspection level | Decide how strict your inspection will be | Matches quality needs |

| Set aql value | Pick the acceptable quality level for defects | Aligns with buyer/supplier goals |

| Find sample size | Use the table to see how many units to inspect | Balances effort and accuracy |

| Check defect limits | See how many defects are allowed in the sample | Guides accept/reject decisions |

You use aql tables to make sure your inspection aligns with industry standards. The table helps you decide how many units to sample from a shipment and the acceptable number of defects. This process ensures that your quality control remains objective and meets the expectations of both buyers and suppliers. You rely on acceptance sampling to make these decisions quickly and fairly.

Aql tables give you confidence in your inspection results. You know exactly when a batch is acceptable and when it fails to meet your standards. This clarity supports consistent quality and builds trust in your inspection process.

How to Use an AQL Table for Inspections

Determining Lot Size

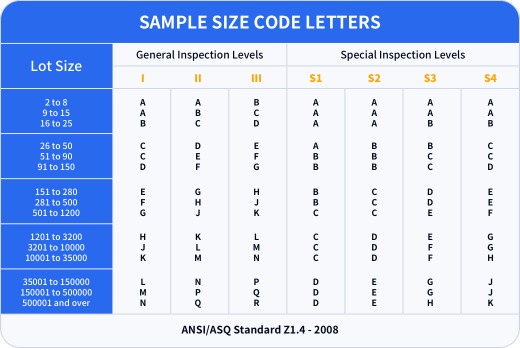

You start every aql inspection by identifying your lot size. The lot size refers to the total number of units in the batch you plan to inspect. This number forms the foundation for your sampling plan. You use the acceptable quality level table to match your lot size with the correct sample size. The sample size determines how many units you need to check for defects. You rely on the ANSI/ASQ Z1.4 standard to calculate the sample size for your quality inspection.

- Lot size equals the total batch quantity.

- The inspection level you select influences the sample size.

- You use the aql table to find the sample size and defect limits.

- The acceptable number of defects depends on your chosen aql value.

- Aql tables categorize defects as critical, major, or minor.

- You use the table to determine the acceptable number of defects for each defect type.

You must always confirm the lot size before you begin sampling. This step ensures your aql sampling plan matches the actual batch and supports reliable quality control.

Choosing Inspection Level

You select an inspection level based on your product risk, budget, and inspection goals. The acceptable quality level table offers several inspection levels, each with a different impact on sample size and defect limits. General inspection levels (I, II, III) are standard for most product inspections. Special levels (S-1, S-2, S-3, S-4) apply to sensitive products or unique situations.

| Inspection Level Type | Levels | Description |

|---|---|---|

| General Levels | I, II, III | Standard inspections; Level II is most common. |

| Special Levels | S-1, S-2, S-3, S-4 | Specific inspections for sensitive products. |

General inspection level II is the default for most aql inspections. You choose level I if inspection costs are high compared to handling non-conforming batches. Level II fits when costs are equal. Level III works best when inspection costs are low and you need stricter quality assurance. Higher levels require larger sample sizes and stricter defect limits. You select lower levels for destructive testing or when inspection costs are high.

| Inspection Level Type | Description | Impact on Sample Size and Defect Limits |

|---|---|---|

| Special Inspection Levels | S-1, S-2, S-3, S-4 | Higher levels require larger sample sizes and stricter defect limits. |

| General Inspection Levels | I, II, III | More discriminative levels lead to increased sample sizes and lower defect thresholds. |

As you move from General I to General III, the ratio of sample size to lot size increases. This means higher inspection levels demand more samples to maintain quality assurance. You adjust your inspection level based on product stability, risk, and cost considerations.

Setting Acceptance Quality Limit

You set the acceptance quality limit to define how many defects you can tolerate in your sample. The aql value reflects your acceptable quality level for each defect type. You use the aql chart to select the right value for your product inspections. Tighter aql limits apply to critical defects, while more lenient standards fit minor cosmetic flaws.

| Factor | Description |

|---|---|

| Budget constraints | Higher sampling levels cost more but increase confidence in results. |

| Risk level of the product | Stricter aql levels apply to high-risk products like medical devices. |

| Supplier trustworthiness | Reliable suppliers may require less stringent inspections. |

| Destructive testing requirements | If inspections destroy samples, you minimize sample size. |

You consider budget, risk, supplier history, and testing requirements when setting your acceptance quality limit. Different aql thresholds apply based on product risk. You use tighter standards for functional checks and allow flexibility for minor flaws. The aql table helps you balance quality control with practical production needs.

Tip: Always document your chosen aql value and inspection level before starting acceptance sampling. This step ensures transparency and supports consistent conformity decisions.

You use aql tables to guide every step of your inspection process. The tables help you select the right sample size, set defect limits, and make objective decisions about batch acceptance. You rely on aql sampling plans to maintain high quality standards and deliver reliable quality assurance.

Interpreting AQL Table Results

Sample Size and Defect Limits

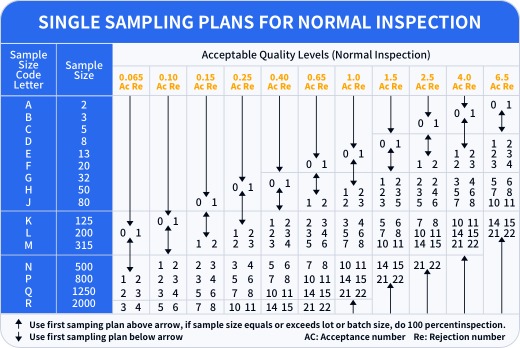

You use theacceptable quality level tableto determine how many units you need to inspect from each batch. The table guides you in selecting the correct sample size based on your lot size and chosen inspection level. You find the intersection of your lot size and inspection level on the aql chart. This intersection shows you the sample size for your aql inspection. You then check the aql limits for critical, major, and minor defects. The table lists the maximum number of defects you can accept in your sample before you must reject the batch.

Tip: Always confirm your sample size and defect limits before starting product inspections. This step ensures your quality inspection follows the correct sampling plans and supports reliable quality control.

Aql tables categorize defects to help you maintain objectivity. You use these categories to set clear thresholds for each defect type. This process supports consistent quality assurance and conformity decisions.

Accept or Reject Decisions

You make accept or reject decisions by comparing the number of defects found in your sample against the limits set in theaql table. If the number of defects stays within the acceptable quality level, you accept the batch. If the defects exceed the acceptance quality limit, you reject the batch. This method ensures your decisions remain objective and consistent across all inspections.

| Criteria Type | Description |

|---|---|

| AQL Levels | Define thresholds for critical, major, and minor defects. |

| Defect Count | Compare the number of defects found during inspection against these thresholds. |

| Decision Outcome | Accept or reject the batch based on the comparison results. |

Aql tables provide standardized sampling plans and clear acceptance criteria. You rely on these tables to align your decisions with industry standards. This approach ensures that different inspectors reach the same conclusion when using the same aql sampling plan. You maintain uniformity in your quality assurance process and support fair acceptance sampling.

- Aql tables provide standardized sampling plans that guide inspectors in their decision-making process.

- They categorize defects, which helps in maintaining objectivity in quality assessments.

- The clear acceptance and rejection criteria ensure alignment in decisions made by different inspectors.

You use aql inspections to make quick, reliable decisions about batch conformity. The acceptable quality level table helps you balance efficiency with strict quality standards. You deliver consistent results in every quality inspection.

Practical Example Using an AQL Table

Step-by-Step Walkthrough

You can see how an acceptable quality level table guides your inspection decisions by walking through a real scenario. Imagine you receive a shipment of 13,000 suits. You and your supplier agree on the following aql limits: critical defects at 0.0%, major defects at 2.5%, and minor defects at 4.0%. You select General Inspection Level II, which is standard for most aql inspections.

Follow these steps to use the aql tables:

1. Determine the lot size. Here, you have 13,000 units.

2. Choose the inspection level. You select Level II for balanced rigor.

3. Find the sample size code letter using the acceptable quality level table. For 13,000 units at Level II, the code letter is 'M'.

4. Refer to the aql tables to find the sample size for code letter 'M'. You need to inspect 315 units.

5. Set the acceptance quality limit for each defect type:

- For critical defects, any defect leads to rejection.

- For major defects, accept the batch if you find 14 or fewer; reject if you find 15 or more.

- For minor defects, accept if you find 21 or fewer; reject if you find 22 or more.

6. Inspect the 315 sample units. Record the number of defects in each category.

7. Compare your results to the aql limits. If the defects are within the acceptable range, you accept the batch. If not, you reject it.

Note: This process ensures your acceptance sampling remains objective and supports conformity with yourquality standards.

Key Insights

You gain several important insights by applying aql inspections in this scenario:

| Insight | Description |

|---|---|

| Structured Sampling Plan | The aql approach gives you a systematic way to assess product quality and balance risk. |

| Comprehensive Evaluation | You evaluate different defect types, which improves your decision-making for batch acceptance. |

| Risk Management | The aql and acceptance quality limit protect both you and your supplier from unacceptable quality. |

| Optimized Supply Chain Processes | Efficient aql inspections speed up delivery and improve your supply chain. |

| Strengthened Brand Reputation | Consistent quality builds trust and supports a positive reputation. |

| Compliance with Industry Standards | Using aql tables helps you meet regulations and support international trade. |

| Increased Operational Control | You gain better visibility into quality and can make data-driven improvements. |

You see that aql tables and sampling plans help you make clear, data-driven decisions. You maintain high quality level, ensure conformity, and keep your inspections efficient.

Common Questions About Acceptable Quality Level

Interpreting Results

You often face questions when you interpret results fromaql inspections. You might wonder what the numbers in aql tables mean for your batch. When you inspect a sample, you compare the number of defects found to the acceptable limits set by your sampling plans. If the defects stay within the acceptable range, you approve the batch. If the defects exceed the quality level, you reject it. You must remember that aql does not guarantee zero defects. It sets a reference point for conformity, helping you decide if the batch meets your standards.

Experts recommend several strategies to avoid misunderstandings about aql results:

| Recommendation | Explanation |

|---|---|

| State aql explicitly in contracts | This helps clarify what aql commitments mean to avoid misunderstandings. |

| Provide supplier training | Training ensures that suppliers understand the implications of aql and its role in quality control. |

| Emphasize aql is not a defect guarantee | Clarifying that aql is a reference point helps prevent misconceptions about defect rates. |

You should always communicate your acceptable quality level clearly. You need to ensure that everyone involved in inspections understands how aql tables work and what the results mean for product acceptance.

Handling Borderline Cases

You sometimes encounter borderline cases during aql inspections. These cases occur when the number of defects found in your sample matches the acceptable limit exactly. You must decide whether to accept or reject the batch. In these situations, you rely on the rules set by your sampling plans. If the defect count equals the acceptable threshold, you accept the batch. If the defects exceed the limit by even one, you reject it.

You can use these tips to handle borderline cases:

- Review your inspection records to confirm the defect count.

- Communicate your decision to suppliers and document the outcome.

- Use consistent criteria for all inspections to maintain fairness.

You maintain objectivity by following the aql tables and sampling plans. You ensure that your decisions support conformity and uphold your quality standards. You build trust in your inspection process by applying the same rules to every batch.

You rely on acceptable quality level tables to guide every stage of your inspection process. The following table shows how these tables support consistent and objective decisions:

| Stage | Description |

|---|---|

| Sampling | You select a random set of items from the batch. |

| Inspection | You check each item for defects. |

| Counting Defects | You record the number of defective items. |

| Comparison | You compare results to the AQL limit. |

| Decision | You accept or reject the batch based on clear criteria. |

Understanding acceptance quality limits helps you adjust your quality control strategy. You identify issues early and improve reliability. Apply these steps to strengthen your inspection outcomes and maintain high standards.

FAQ

What does the maximum allowable number of defects mean in AQL inspections?

You use the maximum allowable number of defects to decide if a batch passes or fails. This number sets a clear limit for defects found during sampling. You compare your inspection results to this threshold.

How do you apply inspection criteria when using an AQL table?

You select inspection criteria based on product type and risk. The table guides you in choosing sample size and defect limits. You follow these criteria to ensure consistent quality checks.

What happens if your inspection results match the acceptance and rejection criteria exactly?

You accept the batch if defects equal the threshold. You reject it if defects exceed the limit. This rule ensures you make objective decisions and maintain fairness in your inspection process.

Can you adjust AQL levels for different products?

You can set different AQL levels for each product category. You consider risk, customer requirements, and supplier reliability. You document these levels before starting inspections to support clear communication.

Why is it important to record inspection results?

You record inspection results to track quality trends and support future decisions. This practice helps you identify recurring issues and improve your quality control process.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.