You need reliable inspection tools for quality control to ensure top performance in your operations. These tools include manual devices, digital instruments, software solutions, and basic quality control tools. You will find measuring tapes, calipers, multimeters, hardness testers, and environmental chambers among the most commonly used inspection tools for quality control. Companies that use inspection tools for quality control experience higher accuracy and efficiency in detecting defects. Inspection tools for quality control also help you meet compliance standards and reduce costly errors. If you want to improve consistency and minimize losses, inspection tools for quality control provide the foundation for success.

Key Takeaways

- Reliable inspection tools enhance accuracy and efficiency in quality control, helping you detect defects early.

- Digital devices automate measurements and provide real-time data, reducing human error and improving inspection speed.

- Quality inspection software streamlines data management, allowing for customized workflows and instant analytics.

- Basic quality control tools, like checklists and control charts, are essential for monitoring and improving product quality.

- Regular quality inspections ensure compliance with industry standards, reducing the risk of costly penalties and recalls.

Types of Inspection Tools

Manual Tools

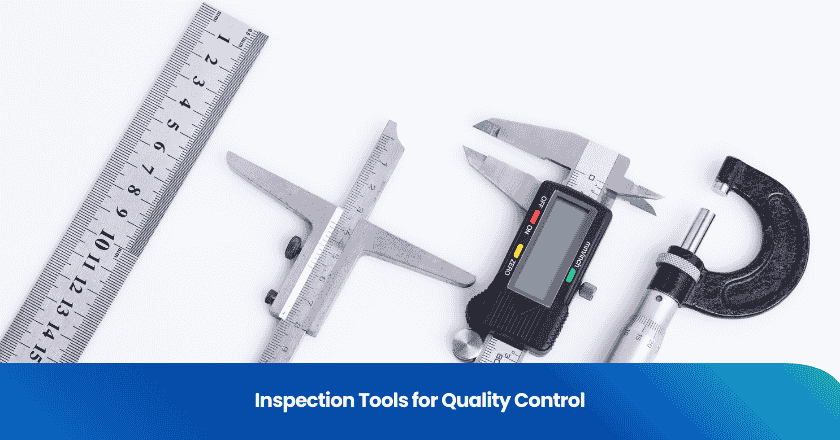

Manual inspection tools form the foundation of quality control in many industries. You use these tools to perform hands-on measurements and visual checks. Common examples include calipers, micrometers, measuring tapes, and gauges. These instruments help you verify dimensions, tolerances, and surface finishes. Manual inspections often require skilled operators who can interpret results accurately.

Manual inspections are susceptible to errors, inconsistencies, and delays. You may miss details or spend extra time cleaning up data. Human judgment can introduce variability, which affects the reliability of your results.

You rely on manual tools for tasks that demand flexibility and direct observation. However, you should recognize their limitations in accuracy and speed compared to digital devices.

Digital Devices

Digital devices have transformed the way you conduct quality inspections. These tools automate measurements, capture data instantly, and reduce the risk of human error. You can use machine vision cameras, sensors, and advanced testing equipment to monitor product quality in real time.

| Device Type | Key Features |

|---|---|

| Machine Vision Cameras | Automate inspection processes and provide real-time feedback on product quality. |

| Sensors | Collect quality data and monitor various parameters during inspections. |

| Testing Equipment | Used for physical testing of products to ensure they meet specifications. |

| Data Collection Software | Gathers data from inspections for analysis and reporting. |

| Analytics Platforms | Analyze collected data to identify trends and areas for improvement. |

| Integration Tools | Connect with existing manufacturing systems for seamless operation. |

You benefit from digital defect capture, measurement modules, and real-time dashboards. Inspectors log defects directly on mobile devices, compare actual measurements against specifications, and track inspection progress. You can customize workflows and tolerances to match your requirements. Offline capability allows you to continue inspections without internet access and sync data later. Automated reports provide instant analytics and images.

- Digital inspections enhance accuracy, speed, and provide real-time visibility.

- Digital tools streamline workflows, allowing for direct data collection in the field with structured forms.

- Real-time data capture enables immediate identification of defects, so you can take corrective actions quickly.

- Automated scheduling and notifications ensure timely inspections and reduce delays.

- IoT integration for measurement conformity minimizes human errors and speeds up inspections.

- Comprehensive analytics and reporting offer insights that help you improve your quality control processes.

You should consider digital devices if you want to boost efficiency and maintain consistent product standards. Automated inspection systems further enhance your ability to detect and address defects promptly.

Quality Inspection Software

Quality inspection software plays a critical role in modern quality control. You use these platforms to manage, analyze, and report inspection data. Quality inspection software supports customized workflows, digital checklists, and real-time dashboards. You can create inspection forms tailored to your products and processes.

| Inspection Type | Function |

|---|---|

| Pre-Production Inspection | Assesses factory readiness and quality of raw materials before manufacturing begins. |

| In-Production Inspection | Conducts quality checks during production to identify and correct defects before completion. |

| Pre-Shipment Inspection | Verifies finished goods to ensure they meet quality requirements before delivery. |

| Container Loading Control Inspection | Confirms quantity and quality of goods being loaded, ensuring proper labeling and packaging. |

| Production Monitoring | Daily checks at the manufacturing site to enforce quality standards and eliminate defects. |

Quality inspection software enables you to log defects, compare measurements, and integrate product details from purchase orders and styles. You track inspection progress, first-hit rates, and defect trends using real-time dashboards. You can configure workflows and tolerances to match your brand requirements. Offline capability lets you continue inspections without internet access and sync data later. Automated reports generate instant analytics with images.

Quality inspection software supports document control, audit management, risk assessment, and supplier quality management. You can integrate these platforms with ERP systems, manage corrective actions, and access operational insights in real time. Cloud-based solutions provide teams with instant access to inspection data, enabling collaboration and faster decision-making.

You see significant improvements in defect reduction and compliance when you implement quality inspection software. Real-time inspection data allows you to identify and fix issues immediately, preventing them from escalating. This proactive approach improves operational efficiency and enhances product quality. Companies that digitize their inspection process often reduce inspection and rework time by 50%-60%. You benefit from automated workflows, ready-made templates, and customizable inspection forms.

You can learn from industry leaders who use quality inspection software to eliminate defects at the source, analyze root causes, and monitor quality metrics in real time. These platforms help you maintain compliance with safety standards and continuously improve your processes.

Basic Quality Control Tools

Basic quality control tools provide you with essential methods for monitoring and improving product quality. You use these tools to identify defects, analyze trends, and implement corrective actions. Common examples include checklists, control charts, Pareto diagrams, and cause-and-effect diagrams.

You rely on checklists to ensure that inspection steps are followed consistently. Control charts help you monitor process stability and detect variations. Pareto diagrams allow you to focus on the most significant issues affecting quality. Cause-and-effect diagrams assist you in identifying root causes of defects.

You can combine basic quality control tools with quality inspection software to enhance your inspection process. Digital platforms allow you to create and manage checklists, generate charts automatically, and analyze data efficiently. You gain deeper insights into your operations and make informed decisions to improve quality.

Tip: You should integrate basic quality control tools with digital solutions to maximize accuracy and efficiency in your inspections.

You use these tools throughout different stages of the inspection process, including pre-production, in-production, pre-shipment, and container loading control. Production monitoring ensures that you enforce quality standards and eliminate defects daily.

Why Quality Inspections Matter

Product Consistency

You rely on quality inspections to maintain consistent standards in your products. When you implement regular inspections, you identify issues early and track improvements over time. This process helps you deliver reliable products to your customers. Quality measurement systems and key performance indicators (KPIs) play a vital role in this effort. They allow you to assess manufacturing performance and monitor product quality.

| Evidence Point | Description |

|---|---|

| Quality Measurement Systems | Help identify issues and track improvements to maintain consistent product standards. |

| Quality Control KPIs | Provide measurable values to assess manufacturing performance and product quality. |

| Role of Quality Control | Ensures product consistency and reliability, reducing waste and optimizing production efficiency. |

You see the benefits of quality inspections in reduced waste and improved production efficiency. Consistent products build trust with your customers and strengthen your reputation in the market.

Regulatory Compliance

Quality inspections help you meet strict regulatory requirements across different industries. You must follow specific guidelines to ensure your products are safe and compliant. Regular inspections verify that your processes align with industry standards and legal mandates.

| Industry | Regulatory Requirements |

|---|---|

| Chemical industry | REACH regulation, CLP regulation, GHS; strict monitoring of production processes and regular analyses. |

| Pharmaceutical industry | Good Manufacturing Practices (GMP), FDA regulations, EMA guidelines; clinical studies and process validation. |

| Food and beverage | HACCP plans, FDA, EU Food Hygiene Regulation; microbiological testing and strict supply chain controls. |

| Medical devices | ISO 13485, FDA 21 CFR Part 820, MDR; risk assessments and process validation methods. |

| Cosmetics industry | EU Cosmetics Regulation, GMP for cosmetic products; toxicological assessments and ingredient testing. |

| Biotechnology | GMP for biopharmaceutical products, FDA biologics regulations; validation processes and microbiological controls. |

You avoid costly penalties and recalls by following these regulations. Quality inspections provide documentation and evidence that your products meet all necessary standards.

Defect Reduction

You use quality inspections to detect and address defects before they reach your customers. Early identification of problems reduces costs associated with rework, scrap, and product recalls. This approach improves profitability and customer satisfaction.

| Benefit | Description |

|---|---|

| Reduced scrap and rework | Early detection avoids cascading rework downstream. |

| Minimized warranty claims | Products leaving the factory meet specifications. |

| Lower total cost of quality | Investing in inspection prevents far more expensive failure costs. |

- Identifying and addressing defects early helps reduce costs associated with rework, scrap, and product recalls.

- Ultimately improves profitability.

Quality inspections serve as your frontline defense against defects. You protect your brand and ensure that only high-quality products reach the market.

Challenges in Quality Inspections

Human Error

You face human error as a major challenge in quality inspections. Fatigue, distractions, and lack of proper procedures often lead to mistakes. These errors can result in missed defects or inaccurate measurements. You can address these issues by focusing on prevention and detection strategies. Prevention involves designing systems that minimize errors, while detection helps you identify mistakes after they occur.

| Common Sources of Human Error | Mitigation Strategies |

|---|---|

| Fatigue | Fatigue Management |

| Distractions | Workplace Ergonomics |

| Lack of Proper Procedures | Standard Operating Procedures |

You also need to consider factors such as manpower, material, method, machine, measurement, and miscellaneous influences. By improving training and standardizing procedures, you reduce the risk of human error in your inspection process.

Time Constraints

You often work under tight deadlines during quality inspections. Time pressure can affect your ability to focus and recall important information. Studies show that limited time influences decision-making and may reduce the effectiveness of inspections. Both younger and older inspectors can maintain selective memory under time constraints, but rushing increases the chance of missing defects.

- The study investigates how being short on time affects the ability to selectively encode and recall valuable information.

- Time pressure can influence decision-making, which is relevant to the effectiveness of quality inspections.

- Findings suggest that both younger and older adults can maintain selective memory under time constraints, indicating potential implications for quality inspection processes.

You improve outcomes by planning inspections carefully and allocating enough time for each step. Prioritizing critical checkpoints helps you maintain accuracy even when schedules are tight.

Data Limitations

You encounter data limitations that impact the results of quality inspections. Incomplete, duplicate, expired, irrelevant, or inaccurate data can lead to poor decisions and unreliable analysis.

| Data Quality Issue | Description | Impact on Quality Inspection Outcomes |

|---|---|---|

| Incomplete Data | Lacks essential records or fields. | Leads to inaccurate analysis and decisions. |

| Duplicate Data | Same information recorded multiple times. | Skews analysis, causing errors like overestimation. |

| Expired Data | Outdated information that no longer reflects reality. | Results in analyses that are no longer accurate. |

| Irrelevant Data | Data that does not contribute to analysis. | Increases costs and security risks. |

| Inaccurate Data | Fails to represent underlying information correctly. | Leads to incorrect analysis and decisions. |

You strengthen your inspection process by ensuring data quality. Regular audits and validation checks help you maintain reliable records and support better decision-making.

Benefits of Modern Inspection Tools

Accuracy

You achieve higher accuracy in quality inspections when you use modern inspection tools. Advanced mapping and measurement technologies reveal gaps that traditional methods often miss. For example, traditional utility records frequently under-document infrastructure. Subsurface Utility Engineering (SUE) mapping identifies 160% more utility infrastructure than older records. Only 32% of utility footage from One Call records aligns within two feet of SUE data. About 21% of utilities in One Call records deviate by over 20 feet compared to SUE data. These improvements show how modern tools help you detect discrepancies and avoid costly mistakes. You can trust your inspection results and make informed decisions.

Tip: Use digital mapping and measurement tools to minimize errors and improve the reliability of your quality inspections.

Efficiency

Modern inspection tools help you complete quality inspections faster and with fewer resources. You streamline your workflow and reduce manual tasks. The following table highlights key metrics that measure efficiency gains:

| Metric | Description |

|---|---|

| Inspection Speed | Time taken to complete inspections |

| Cost Savings | Reduction in costs associated with inspections |

| Accuracy | Improvement in the precision of inspection results |

| Safety Improvements | Enhancements in safety during inspection processes |

You see dramatic reductions in inspection time. Stantec reported a 90% decrease in time spent on dam inspections. Consor reduced photo upload time from a full day to just 15–60 minutes. These results show how modern tools help you save time and money while maintaining high standards.

Compliance

You meet regulatory requirements more easily when you use modern inspection tools. These tools help you document and verify every step of your quality inspections. The following table shows common compliance standards addressed by modern inspection tools:

| Compliance Standard | Industry Focus | Importance |

|---|---|---|

| GS1 | Food & Pharma | Label accuracy and compliance |

| ISO | Food & Pharma | Quality assurance and regulatory compliance |

| FDA | Food | Accurate ingredient and allergen labeling |

| USDA | Food | Nutritional information standards |

| Serialization | Pharma | Patient safety and legal compliance |

| Traceability | Pharma | Product recalls and safety monitoring |

Label accuracy is crucial in pharmaceuticals to prevent misuse and legal issues. Food labels must comply with FDA, USDA, and EU regulations to avoid recalls due to allergen mislabeling. Regular quality inspections help you maintain compliance and reduce legal risks.

Selecting Inspection Tools for Quality Control

Key Features

When you select inspection tools for your quality control processes, you should focus on features that support accuracy and efficiency. The right features help you streamline inspections and improve your quality management system. The table below highlights essential features to consider:

| Key Feature | Description |

|---|---|

| Real-Time Monitoring | Enables continuous tracking of quality control activities, so you can identify issues early. |

| Data Collection and Reporting | Centralizes inspection results and corrective actions, making data-driven decisions easier. |

| Inspection Checklists | Ensures systematic inspections and consistent application of quality standards. |

| Mobile Accessibility | Allows inspectors to record results on-site for timely and accurate real-time data collection. |

| Integration with Other Systems | Ensures quality control activities connect with your quality management system and reports. |

Tip: Prioritize tools that offer real-time data collection and seamless integration with your existing quality management system.

Evaluation Criteria

You need clear criteria to evaluate inspection tools for your quality control processes. Start by assessing how well each tool fits your operational needs. Look for user-friendly interfaces and compatibility with your current systems. Check if the tool supports real-time data collection and reporting. Consider the scalability of the solution as your business grows. Review the level of technical support and training available. Reliable tools should enhance your quality management system and adapt to changing requirements.

- Does the tool support your inspection workflow?

- Can you customize checklists and reports?

- Will it integrate with your other business systems?

- Is real-time data collection available for immediate decision-making?

Budget Considerations

You must balance performance and cost when investing in inspection tools. Capital expenditures (Capex) include the initial purchase of hardware, software, and any infrastructure upgrades. For example, high-resolution cameras and specialized lighting may increase upfront costs but deliver long-term savings by reducing manual labor. Automation can lower ongoing expenses, especially in regions where labor costs are high. Consider both the immediate investment and the potential for future cost reductions as you improve your quality control processes.

Implementation Steps

Integration Process

You can achieve a smooth transition when integrating inspection tools into your quality control process by following a clear, step-by-step approach:

1. Define your inspection requirements before selecting any system. This ensures you address your specific quality goals.

2. Start with pilot projects. These small-scale trials help you demonstrate value and refine your approach.

3. Set up optimal lighting and imaging conditions. Proper setup improves the performance of your inspection tools.

4. Develop procedures for handling and documenting defects. Clear guidelines keep your process consistent.

5. Collect and analyze data continuously. This practice helps you improve both inspection and production.

6. Maintain regular communication between your quality, production, and engineering teams. Open dialogue supports successful integration.

You should also look for opportunities to introduce automated workflows. These workflows can streamline data collection and reporting, making your process more efficient.

Training

Effective training ensures your team uses new inspection tools with confidence. You can choose from several proven methods:

- Instructor-led training gives your staff direct access to expert guidance.

- E-learning and online courses offer flexibility, especially for remote teams.

- Workshops and seminars provide hands-on experience with immediate feedback.

- Mentorship and coaching pair experienced employees with new users, encouraging knowledge transfer.

You should tailor your training program to your team’s needs. Automated workflows can simplify training by standardizing procedures and reducing manual steps.

Tip: Combine different training methods to maximize engagement and retention.

Continuous Improvement

You need to optimize your inspection process over time. Several strategies support ongoing improvement:

- PDCA (Plan, Do, Check, Act) encourages you to make small, regular changes and learn from results.

- Gemba Walks let you observe workflows directly, helping you spot bottlenecks and improvement opportunities.

- Kanban boards visualize tasks and progress, improving communication and accountability.

You should review your inspection data regularly and adjust your process as needed. Continuous improvement keeps your quality control system effective and responsive.

Inspection tools help you achieve greater accuracy, efficiency, and compliance in quality control. Selecting and implementing the right tools strengthens your inspection process and supports continuous improvement. To upgrade your current approach, consider these industry best practices:

1. Prioritize high-risk equipment.

2. Define suitable inspection methods.

3. Set inspection frequency based on risk.

4. Perform inspections according to plan.

5. Document findings in detailed reports.

6. Implement corrective actions.

7. Periodically review and update your program.

8. Leverage digital tools for ongoing monitoring.

Regularly reviewing your inspection process ensures you maintain high standards and adapt to changing requirements.

FAQ

What are the most common inspection tools for quality control?

You often use calipers, micrometers, measuring tapes, and digital sensors. Quality inspection software and basic checklists also play a key role in maintaining standards.

How do digital inspection tools improve accuracy?

Digital inspection tools capture measurements instantly and reduce human error. You benefit from automated data collection, real-time feedback, and precise analytics.

Why should you integrate inspection tools with software solutions?

You streamline your workflow and centralize data. Integration allows you to track defects, generate reports, and ensure compliance with industry standards.

How often should you perform quality inspections?

You should schedule inspections based on risk, production volume, and regulatory requirements. Regular checks help you detect issues early and maintain consistent product quality.

What training methods work best for new inspection tools?

You can use instructor-led sessions, online courses, and hands-on workshops. Combining these methods helps your team learn quickly and apply new skills effectively.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.