In the global fashion and luxury goods industry, the structural integrity and chemical safety of metal hardware—such as buckles, zippers, and rivets—are critical to brand reputation and consumer health. Nickel (Ni) is a versatile transition metal frequently utilized for its exceptional luster, hardness, and corrosion resistance. However, it is also a primary sensitization agent responsible for allergic contact dermatitis (ACD). To mitigate physiological risks and ensure product longevity, manufacturers must implement rigorous Ni-ion migration analysis and accelerated corrosion protocols. Adhering to international standards like REACH Annex XVII and ASTM F2923 is not merely a regulatory hurdle but a technical baseline for high-performance industrial products.

Key Takeaways

- Nickel release testing (EN 1811:2023) quantifies the migration of Ni-ions into human skin through simulated perspiration.

- The REACH regulation restricts nickel release to ≤ 0.5 µg/cm²/week for products in prolonged contact with skin.

- Corrosion checks using Salt Spray (NSS/CASS) and Damp Heat identify structural weaknesses in electroplating layers.

- Professional apparel quality control must include wear simulation (EN 12472) to verify the durability of protective coatings.

- Sustainability in metal finishing is driving the adoption of nickel-free plating technologies like Tin-Cobalt or PVD coatings.

- Regular factory audits and on-site testing are essential to prevent 'quality fade' during mass production of metal trims.

The Chemistry of Nickel Allergy and Perspiration Interaction

The mechanism of nickel allergy is an electrochemical process. When a nickel-containing alloy comes into contact with human perspiration—a complex mixture containing sodium chloride (NaCl), urea, and lactic acid—the acidic environment triggers the ionization of nickel. These Ni2+ ions penetrate the skin, where they bind to epidermal proteins, creating an antigen that triggers an immune response. According to clinical data from the American Academy of Dermatology, this sensitization is irreversible, making prevention through chemical restriction the only viable public health strategy.

Simulated Perspiration Formulation

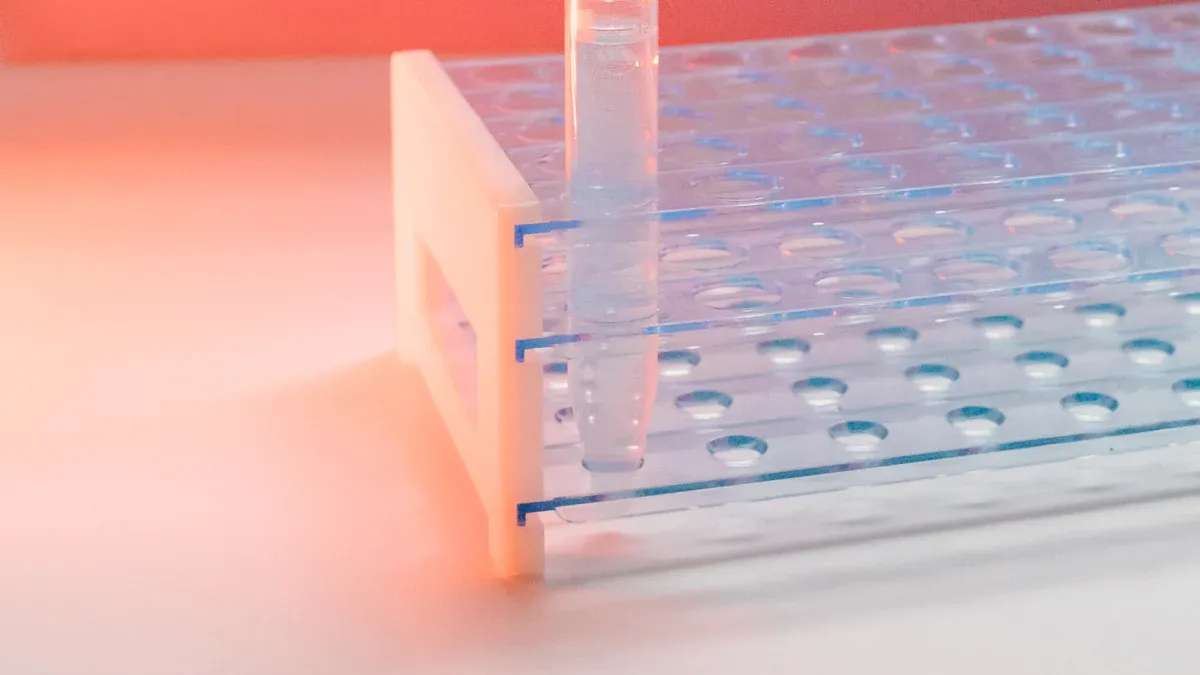

To replicate this interaction in a laboratory environment, technicians utilize a standardized artificial sweat solution. The technical parameters of the solution are strictly controlled to maintain a pH of approximately 6.5, representing the average surface acidity of human skin. This allows for an accurate measurement of how much nickel will leach from a buckle or bra hook over a seven-day immersion period.

| Solution Component | Concentration (g/L) | Technical Function |

|---|---|---|

| Sodium Chloride (NaCl) | 5.0 | Triggers electrolytic conductivity |

| Urea (CH4N2O) | 1.0 | Simulates organic metabolite interaction |

| Lactic Acid (C3H6O3) | 1.0 | Maintains physiological pH levels |

| Sodium Hydroxide (NaOH) | As required | pH adjustment to 6.5 +/- 0.05 |

Quantitative Nickel Release Analysis: EN 1811:2023

The EN 1811 standard is the internationally recognized method for determining nickel release. The 2023 revision introduced more precise calibration for Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Optical Emission Spectroscopy (ICP-OES). The test result is expressed in μg/cm²/week (micrograms per square centimeter per week).

The Necessity of Wear Simulation: EN 12472

A significant challenge in hardware quality is the use of "Nickel-under-gold" plating. In this process, a nickel layer is used as a leveling agent before a precious metal or lacquer is applied. While a new product may pass the EN 1811 test, the protective coating can wear off within weeks of use. To address this, the EN 12472 standard requires an accelerated wear simulation before Ni-release testing. This involves tumbling the hardware in a specialized media consisting of abrasive paste and walnut shells to simulate two years of consumer use.

Technical Standard Note: If a product is intended for "prolonged skin contact," it must pass the Ni-release test *after* the wear simulation. This ensures that the consumer is protected throughout the entire lifecycle of the fashion accessory.

Corrosion Dynamics and Accelerated Aging Protocols

Beyond chemical safety, metal buckles must resist environmental degradation. Corrosion is an oxidative process that not only destroys the aesthetic appeal of a bag or belt but can also compromise its mechanical function. To verify the integrity of the finish, manufacturers utilize accelerated aging in environmental chambers.

Salt Spray Testing (ASTM B117 / ISO 9227)

Salt spray testing is the industrial standard for evaluating electroplating quality. By exposing metal trims to a concentrated salt mist, technicians can identify porosities in the plating or poor adhesion between layers. For high-end fashion, the Copper-Accelerated Acetic Acid Salt Spray (CASS) test is often preferred, as it better simulates the aggressive combination of humidity and airborne pollutants found in urban environments.

| Test Methodology | Environment Parameters | Technical Application |

|---|---|---|

| Neutral Salt Spray (NSS) | 5% NaCl, 35'C | Routine QC for standard finishes |

| CASS Test | NaCl + CuCl2 + Acetic Acid | High-end Nickel-Chrome plating validation |

| Damp Heat Test | 95% Humidity, 40'C | Tests for blistering and lacquer adhesion |

| Sulfur Dioxide (SO2) Test | SO2 atmosphere, DIN 50018 | Verifies resistance to industrial acid rain |

Global Regulatory Compliance and Market Access

Navigating the complex landscape of global chemical regulations is essential for market entry. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation in the European Union is currently the strictest framework for nickel. In the United States, while there is no federal mandate for adult hardware, the Consumer Product Safety Improvement Act (CPSIA) and ASTM F2923-14 impose strict Ni-release limits for children's jewelry and accessories.

Achieving compliance requires a robust quality assurance program. For high-volume production, a factory audit is the only way to verify that the manufacturer isn't 'switching' to lower-cost nickel-heavy alloys after the initial samples have been approved. Regular standardized product inspections must include 'Spot Tests'—qualitative chemical checks that provide an immediate color-change reaction in the presence of nickel.

The Engineering of Nickel-Free Alternatives

As the industry moves toward sustainability and hypoallergenic products, the development of nickel-free alternatives has accelerated. Technical solutions include:

- White Bronze (Copper-Tin-Zinc): Provides a brilliant silver look without the allergenic risk of nickel, though it requires precise electrolytic control to maintain color consistency.

- Physical Vapor Deposition (PVD): A vacuum coating process that deposits thin films of Titanium Nitride or Zirconium. PVD is hypoallergenic and offers superior hardness compared to traditional electroplating.

- Stainless Steel (AISI 316L): Often marketed as 'surgical steel.' While it contains nickel, the metal is bound so tightly within the molecular matrix that the release rate is well below detection limits.

Practical Guide for Professional Procurement

When sourcing metal buckles and trims, technical buyers should look beyond price and visual finish. A technical verification checklist should include:

- Request for Mill Test Reports (MTR): Verify the base alloy composition (e.g., Lead content in brass or Zinc purity in die-castings).

- Certification Review: Ensure the laboratory test reports follow the latest EN 1811:2023 protocols rather than outdated versions.

- Plating Thickness Verification: Use X-ray Fluorescence (XRF) to measure the thickness of the protective lacquer and precious metal layers. A lacquer layer thinner than 10 microns is likely to fail wear simulation.

- Assessment of Surface Roughness: Highly polished surfaces have a lower effective surface area, which can technically reduce the Ni-ion release rate compared to matte or brushed finishes.

By prioritizing components that have passed standardized quality inspection methods, brands can ensure they deliver products that are safe for the wearer and durable enough to withstand the rigors of daily fashion use.

Ready to secure your product quality before shipment?

As your third-party inspection, testing & certification partner in China, TradeAider supports brands and sourcing teams across the entire production process, helping you identify quality risks early, ensure compliance, and strengthen your team’s capabilities before shipment.

Book an Inspection or Testing Service with TradeAider today, or for tailored solutions and expert guidance, contact us at services@tradeaider.com or submit the request form on the right. →

Frequently Asked Questions (FAQ)

Is 'Nickel-Free' truly zero nickel?

In technical terms, 'Nickel-Free' usually refers to a product that meets the release limits of REACH (≤ 0.5 µg/cm²/week). It does not necessarily mean the alloy contains zero atoms of nickel. It means that the nickel present does not migrate out of the metal in quantities sufficient to trigger an allergic reaction.

What is the difference between NSS and CASS tests?

Neutral Salt Spray (NSS) uses a simple saline solution and is used for general corrosion screening. The CASS test adds copper chloride and acetic acid, making it significantly more aggressive. CASS is the technical standard for verifying the durability of decorative Nickel-Chrome plating layers.

How can I identify nickel in a buckle without a laboratory?

While not a substitute for quantitative testing, a 'Dimethylglyoxime (DMG) Spot Test' can be used. When the DMG reagent is applied to a cotton swab and rubbed on the metal, it will turn bright pink if nickel is being released. This is an excellent tool for preliminary factory inspections.

Why do stainless steel buckles sometimes fail nickel release tests?

While 316L grade steel is safe, lower grades like 201 or 304 can release nickel if they are subjected to aggressive polishing or if they have internal impurities. The crystalline structure of the steel dictates how securely the nickel atoms are held within the lattice.

How long does a nickel release test take?

A formal EN 1811 test requires a minimum of 168 hours (7 days) of immersion in artificial sweat. When you include sample preparation, wear simulation (EN 12472), and ICP-MS analysis, the total turnaround time for a technical laboratory report is typically 10 to 14 business days.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.