In the textile manufacturing sector, the performance of terry fabrics—predominantly utilized in towels and bathrobes—is defined by two critical technical parameters: moisture uptake kinetics (water absorbency) and structural pile stability (pile loss rates). For industrial buyers and hospitality procurement managers, these metrics are the definitive indicators of material longevity and user comfort. High absorbency is not merely a tactile preference; it is a function of fiber hydrophilicity and capillary action governed by sinker height and loop density. Conversely, excessive pile loss, or 'linting,' indicates a technical failure in yarn twist engineering or the weaving process. This guide provides an in-depth exploration of the metrological standards and quality control protocols required to ensure that Softline Products maintain their structural integrity after repeated industrial laundering cycles.

Key Takeaways

- Water absorbency is quantified through ASTM D4772, measuring the rate of surface saturation and total moisture capacity.

- Pile loss (Linting) is a mechanical failure of fiber anchoring; standardized tests like CTL WW 104 help predict premature thinning.

- Yarn engineering, such as Zero-twist vs. Ring-spun, dictates the trade-off between tactile softness and durability.

- Professional quality checks must identify the use of temporary hydrophilic softeners that wash away after initial use.

- GSM (Grams per Square Meter) is a poor indicator of absorbency if the yarn quality and loop density are not verified.

- RFID and digital tracking integration allow hospitality sectors to monitor the 'wash-life' of linens and maintain service standards.

The Physics of Capillary Action in Terry Fabrics

The superior absorbency of a high-quality towel is achieved through the physical principle of capillary rise. Terry fabric consists of three yarn systems: the ground warp, the ground weft, and the pile warp. The loops created by the pile warp significantly increase the effective surface area of the fabric. According to research published in textile academic reviews, the pore size between the cotton fibers acts as a micro-channel that pulls moisture away from the skin through surface tension. The technical efficiency of this process is a result of the 'Sinker Height' and the 'Pick-to-Pile' ratio.

Molecular Hydrophilicity vs. Surface Finishes

A frequent technical challenge in procurement is the application of cationic softeners. While these chemicals provide an immediate 'plush' hand-feel, they are inherently hydrophobic (water-repellent) as they coat the fiber surface with a waxy layer. This reduces the capillary action, leading to towels that feel soft but fail to dry the skin. Professional quality control audits use 'Scouring' checks to verify that the fabric maintains its natural hydrophilic properties without over-dependence on temporary chemical coatings.

| Performance Metric | Technical Objective | Industrial Benchmark |

|---|---|---|

| Static Absorption | Total water mass retention | 400% - 500% of fabric weight |

| Dynamic Rate | Time to achieve 100% saturation | < 5 seconds (ASTM D4772) |

| Capillary Rise | Vertical moisture migration speed | Minimum 30mm per 10 minutes |

| Moisture Release | Quick-drying efficiency | 35-40% reduction in mass within 2 hours |

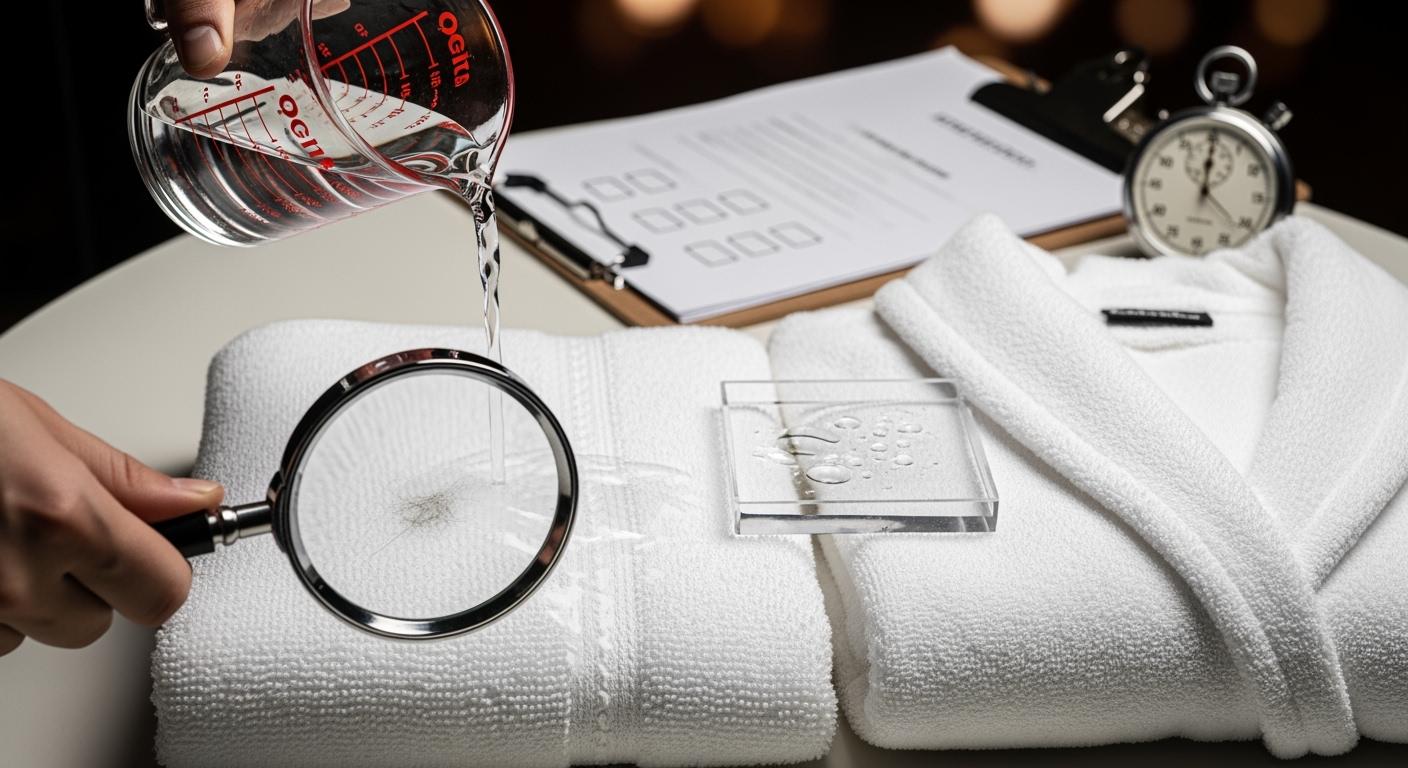

Quantitative Absorbency Testing: Standardized Lab Protocols

Industrial validation of water absorbency requires the elimination of human subjectivity. The definitive standard used in global laboratories is ASTM D4772 (Surface Water Absorption Test). During this procedure, a standardized volume of water is allowed to flow over the fabric specimen held at a 60-degree angle. The mass of water not absorbed is measured to calculate the 'Water Absorption Efficiency.'

Advanced Spectrophotometric Analysis

Modern labs also utilize infrared spectrophotometry to measure 'Moisture Management Properties' (MMT). This technology tracks the speed at which moisture travels from the 'Inner Surface' (skin side) to the 'Outer Surface' (evaporation side). A high 'One-way Transport Index' is critical for bathrobes intended for luxury spas and wellness centers to prevent the wearer from feeling cold after exit from water.

| Standard Type | Technical Method | Usage Scenario |

|---|---|---|

| ASTM D4772 | Timed Water Flow / Retention | Standard retail towel benchmarking |

| ISO 9073-6 | Liquid Strike-Through | Evaluating non-woven or hybrid bath products |

| AATCC 197 | Vertical Wicking of Textiles | Testing heavy-duty bathrobes and robes |

The Mechanics of Pile Loss and Linting Kinetics

Pile loss occurs when individual fibers or entire loops are pulled from the ground structure of the fabric. This is technically quantified as the 'Linting Rate.' In high-speed industrial washing, the mechanical agitation creates shear stress on the loop anchors. If the 'Twist Multiplier' of the yarn is too low, the internal fiber friction cannot resist these forces, leading to a visible thinning of the towel over time.

Loop Anchoring and Yarn Engineering

High-end towels utilize 'Ring-Spun' yarns, where fibers are tightly twisted to create a smooth, durable surface. In contrast, 'Open-End' yarns are cheaper but more prone to breakage and shedding. During pre-shipment inspections, a 'Tension Test' on individual loops (ASTM D 1424) can verify that the pile warp is correctly interlocked with the ground weft. Failure here often leads to 'snagging'—a major cause of linen retirement in hotels.

Technical Standard Note: The CTL WW 104 method is specifically designed for hotel linens. It measures the weight of lint collected after 10 consecutive industrial wash/dry cycles. A loss exceeding 1% of the fabric mass indicates a structural deficiency in the yarn or weave construction.

Manufacturing Quality Assurance and Factory Auditing

Consistency in terry production is achieved by integrating apparel testing and quality control into every stage of the production management lifecycle. It is common for a vendor to submit a high-quality sample while mass-producing units with reduced 'Pick Density' to save material costs. A comprehensive factory audit must verify the following technical checkpoints:

- Weaving Tension Control: Automated looms must have sensors to prevent 'loose loops' that lead to snagging.

- Dye House PH Management: Improper neutralization after dyeing can leave fibers brittle, significantly increasing the pile loss rate.

- Electronic Lint Trapping: Monitoring the volume of waste collected in the finishing department is a key indicator of yarn structural integrity.

- GSM Uniformity: Weighing samples across the width of the fabric roll to prevent side-to-side density variation.

Material Selection: The Impact of Fiber Staple Length

The ultimate limit of absorbency and durability is determined by the raw fiber. 'Long-Staple' cotton (like Turkish or Giza 45) provides fibers that are more than 35mm in length. These longer fibers require fewer 'twist points' to stay anchored, allowing for the spinning of 'Zero-twist' yarns. These yarns are technically superior as the absence of twist leaves the fiber's interior surface open to moisture, increasing absorbency by up to 300% compared to standard short-staple yarns.

Ready to secure your product quality before shipment?

As your third-party inspection, testing & certification partner in China, TradeAider supports brands and sourcing teams across the entire production process, helping you identify quality risks early, ensure compliance, and strengthen your team’s capabilities before shipment.

Book an Inspection or Testing Service with TradeAider today, or for tailored solutions and expert guidance, contact us at services@tradeaider.com or submit the request form on the right. →

Frequently Asked Questions

What is the difference between GSM and absorbency?

GSM (Grams per Square Meter) measures the weight of the fabric. Absorbency measures how much water that weight can hold. While a higher GSM towel *can* hold more water, a 400 GSM towel made of long-staple cotton can technically outperform a 600 GSM towel made of low-grade polyester blends or short-staple cotton in terms of drying speed and comfort.

Why do towels lose their absorbency after using fabric softener?

Fabric softeners contain hydrophobic surfactants that coat the cotton fibers with a thin film of oil/wax. This film significantly increases the contact angle of water droplets, preventing them from entering the capillary pores of the yarn. Professional maintenance teams always recommend avoiding softeners for high-performance linens.

How can I identify 'Quality Fade' in a bulk shipment?

Compare the 'Weight per Dozen' and the 'Loop Height' of the bulk goods against the approved golden sample. A reduction in loop height of even 0.5mm can reduce total absorbency capacity by 10-15%. Utilizing standardized inspection methods is the only way to catch these subtle discrepancies.

Does a high pile loss rate always mean the towel is poor quality?

For the first 2-3 washes, some 'shedding' is normal as loose surface fibers are removed. However, if the pile loss persists beyond the fifth wash, it indicates a technical failure in the 'Twist Multiplier' or 'Sizing' process, and the towel will likely thin prematurely.

What is the typical lifespan of an industrial towel?

In high-intensity hospitality environments, a professional-grade towel should withstand 150 to 200 industrial wash cycles before the absorbency drops below the 80% efficiency threshold. Monitoring this lifecycle is essential for budget forecasting and service quality management.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.