In the textile global supply chain, fabric weight is more than just a measurement; it is a definitive indicator of material value, durability, and functional performance. Sourcing managers and quality engineers must rigorously validate material thickness to prevent 'Quality Fade'—a process where suppliers gradually replace specified high-density fabrics with thinner, cheaper alternatives. When a batch is delivered with even a 5% discrepancy in grams per square meter (GSM), it can lead to catastrophic failures in garment fit, opacity, and bursting strength. Establishing a robust technical framework for metrological weight validation, supported by international standards like ASTM D3776, is the only way to ensure product integrity and protect brand reputation from hidden material shortcuts.

Key Takeaways

- Fabric weight validation (GSM/Oz) is the primary method for detecting the use of substandard yarns or reduced thread counts.

- ASTM D3776 is the definitive industrial standard for small-swatch fabric mass measurement using circular cutters.

- Multi-stage inspections—from greige fabric to finished goods—are required to catch weight manipulation after finishing processes.

- Environmental factors, specifically relative humidity, can alter fabric weight by up to 8%; standardized conditioning is mandatory for accurate data.

- Digital real-time monitoring through a comprehensive quality check system provides the transparency needed to hold vendors accountable.

- Clear technical specifications must include +/- 5% tolerance ranges to differentiate between natural variance and intentional corner-cutting.

The Metrology of Textile Weight: GSM, Oz, and Momme

Textile professionals utilize various units depending on the material type and regional market requirements. Grams per square meter (GSM) is the global metric standard, offering superior precision for mathematical process control. However, sectors like denim and high-density canvas still rely heavily on the imperial Ounces per square yard (Oz/yd2).

Technical Units and Conversion Physics

For silk fabrics, the 'Momme' (mm) is used, representing the weight of a piece of silk 100 yards long and 45 inches wide. One Momme is equivalent to approximately 4.34 g/m2. Understanding these conversions is critical during initial quality inspections to ensure that a '22mm silk' claim isn't actually an 18mm substitute.

| Unit Name | Technical Definition | Standard Application | Precision Benefit |

|---|---|---|---|

| GSM (g/m2) | Mass of 1m x 1m area | T-shirts, Sportswear, Fleece | Highly repeatable for batch comparison |

| Oz/yd2 | Mass of 1yd x 1yd area | Denim, Industrial Canvas | Legacy standard for heavy-duty weaves |

| Momme (mm) | Weight of 100yd x 45in | Silk Charmeuse, Chiffon | Measures fiber density in delicate filaments |

How Suppliers 'Cut Corners': The Anatomy of Quality Fade

Intentional thickness shortcuts often occur through sophisticated means that are difficult to detect via simple visual inspection. Suppliers may reduce the 'picks per inch' (PPI) or 'ends per inch' (EPI) during weaving, or utilize lower-denier yarns while applying heavy chemical 'sizing' or 'filling' agents to artificially inflate the weight of the sample roll.

Chemical vs. Structural Weight

A common shortcut involves using a lighter greige (unfinished) fabric and applying a heavy silicone or starch coating during the finishing stage. While the GSM may initially match the spec, these additives wash away after the first consumer laundry cycle, leaving the garment flimsy and prone to pilling. Robust fabric inspection must include a 'wash-down' test to verify that the specified weight is structural, not chemical.

Technical Alert: Some suppliers intentionally moisture-condition fabric rolls to the maximum allowable limit (e.g., 8-10% regain) before weighing. This 'water-weight' can mask a 15-20 GSM deficiency in the actual fiber content.

Technical Inspection Stages: Catching Discrepancies Early

Verification must be integrated into the production management lifecycle. Relying solely on a pre-shipment report is a high-risk strategy that often leads to rejected shipments and empty retail shelves.

Pre-Production Greige Audit

Before dyeing and finishing, the greige fabric weight must be verified. Since finishing processes like 'scouring' can cause a 3-5% weight loss (due to the removal of natural waxes and oils), the greige must be sufficiently heavy to meet the final finished GSM requirement. During a professional apparel inspection, checking greige density ensures the vendor is not starting with a baseline that makes compliance impossible.

In-Process GSM Profiling

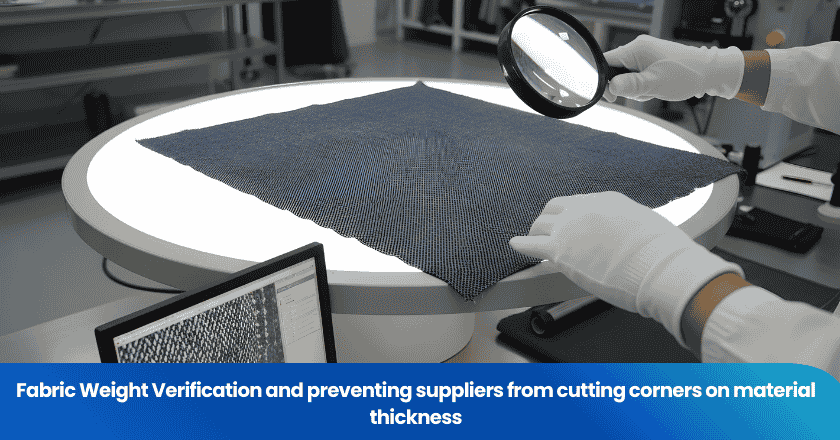

During dyeing and stentering (heat setting), the fabric is stretched under tension. If the stenter speed is too high or the overfeed is insufficient, the fabric will be 'stretched thin,' significantly reducing its thickness and weight. Technicians utilize a calibrated 100cm2 circular cutter to pull samples from the beginning, middle, and end of the production run to ensure uniformity across the entire batch.

| Inspection Stage | Technical Objective | Test Standard |

|---|---|---|

| Raw Material Audit | Validate yarn denier and count | ISO 2060 |

| Pre-Production | Measure greige GSM and width | ASTM D3776 (Method C) |

| During Production | Verify weight after stenter setting | Real-time weigh-bridge sensors |

| Pre-Shipment | Confirm finished weight and recovery | Final Random Sampling (AQL) |

Advanced Laboratory Verification Protocols

For high-stakes sourcing, manual weighing is insufficient. Accredited third-party laboratories utilize standardized conditioning environments (typically 21'C at 65% relative humidity) for 24 hours to ensure all moisture regain is neutralized. Only then is the 'Bone-Dry' or 'Conditioned Weight' calculated.

ASTM D3776: The Circular Cutter Method

This is the most common industrial test for weight verification. Technicians cut five 100cm2 discs from different locations across the fabric width (avoiding the selvages). These discs are weighed on an analytical balance with 0.001g precision. The average weight of these five samples provides the definitive GSM value. Any deviation exceeding +/- 5% of the tech-pack requirement should trigger a 'Hold' on production for further investigation into the weaving/knitting density.

Expert Tip: For knitted fabrics, always measure the 'Bursting Strength' alongside weight. If a supplier has used thinner yarns but achieved the target weight through chemical binders, the fabric will fail the bursting test (ASTM D3786), revealing the structural deficiency.

Implementing Real-Time Digital Monitoring

Transparency is the enemy of corner-cutting. Modern apparel quality inspections now leverage digital floor-to-mobile systems. By requiring the factory to upload digital photos of the GSM scale readings during the 'In-Line' phase, sourcing teams can verify consistency without being physically present.

Key features of an effective monitoring system include:

- Time-Stamped Data: Preventing the factory from using 'old' photos for new batches.

- Automated Variance Alerts: Systems that automatically flag any reading that falls outside the 5% tolerance window.

- Digital Thread Traceability: Linking the final GSM back to the specific lot of yarn used in the knitting machine.

The Role of Factory Audits and Qualification

Before placing an order, a technical factory audit must verify that the vendor possesses the equipment necessary for weight verification. A factory without a GSM cutter, a calibrated scale, and a moisture-controlled conditioning room is technically incapable of ensuring weight consistency. Furthermore, auditors must review the 'Waste Management' records to ensure the factory isn't mixing high-grade yarns with lower-quality recycled fibers to reduce costs at the expense of weight uniformity.

Establishing third-party quality assurance protocols ensures that an independent body verifies the material gauge, providing an unbiased report that serves as a legal safeguard in case of shipment disputes.

Third-party Quality Control Process and Key Quality Checks

Effective manufacturing quality control requires oversight at every stage of an order—from pre-production planning and in-process monitoring to pre-shipment inspection—to ensure consistent workmanship and product compliance. As a third-party inspection service provider, TradeAider provides Inspection & QA Services across the entire production sourcing process to help ensure goods meet defined quality standards. TradeAider assigns experienced inspectors to conduct on-site products inspection in accordance with international inspection protocols and customer-specific requirements, including sampling methods, defect classification, and finished-product assessment. This structured approach reduces the risk of quality fade during mass production.

TradeAider Sampling Plan: ANSI/ASQ Z1.4-2008

Inspections can be performed as either random sampling or 100% full inspection. At TradeAider, we use the globally trusted ANSI/ASQ Z1.4-2008 (AQL) Single Sampling Plan for all inspections. This standard, aligned with ISO 2859-1 and equivalents such as BS6001 and DIN 40080, ensures consistent, reliable quality checks. For a 500-piece order, a General Inspection Level II (G-II) might involve checking 50 units; sampling quantities can also be customized according to client requirements.

AQL Defect Classification:

- Critical: Safety risks (e.g. needles in fill), tolerance 0.

- Major: Functional issues (e.g. failed fill power, significant down leakage). Tolerance 1.5.

- Minor: Aesthetic issues (e.g. slight shading, uncut threads). Tolerance 4.0.

Key On-Site Fabric Inspections and Data Measurement

TradeAider inspectors conduct a comprehensive range of on-site inspections based on fabric type and end-use requirements. In addition to visual appearance checks, fabric inspections focus on material quality, physical performance, and compliance with specifications, including:

• Quantity and Packaging: Verification of fabric yardage/roll length, roll count, width consistency, labeling, and packaging condition.

• Workmanship (Visual Inspection): Checking for fabric defects such as stains, oil marks, holes, snags, color shading, uneven weaving/knitting, broken yarns, and surface contamination.

• Data Measurement: Measuring fabric width, weight (GSM), thickness, density, and conducting on-site tests such as color fastness rubbing tests (dry & wet), dimensional stability checks, and fabric shrinkage sampling where applicable.

• Physical & Performance Tests: Evaluating tensile strength, tearing strength, pilling resistance, abrasion resistance, and elasticity/recovery based on fabric construction and usage requirements.

• Material Verification: Confirming fiber composition (e.g. cotton, polyester, wool, blends) against specifications, checking fabric structure (woven/knitted), and verifying finishing processes such as coating, lamination, or special treatments.

Real-Time Documentation and Reporting Systems

Data transparency is the cornerstone of effective quality assurance. TradeAider inspectors document findings with photos, videos, and precise measurements, leading to a conform, non-conform, or pending verdict. All results are uploaded in real time to the TradeAider Service System.

Clients can access an Online Real-time Report while the inspection is still in progress. This allows for immediate decision-making—pending or non-conforming items are communicated instantly, enabling the client to decide whether products are acceptable or need on-site rectification by the supplier. An Official Report detailing the final situation is provided within 24 hours as standard practice.

Ready to secure your product quality before shipment?

As your third-party inspection, testing & certification partner in China, TradeAider supports brands and sourcing teams across the entire production process, helping you identify quality risks early, ensure compliance, and strengthen your team’s capabilities before shipment.

Book an Inspection or Testing Service with TradeAider today, or for tailored solutions and expert guidance, contact us at services@tradeaider.com or submit the request form on the right. →

Frequently Asked Questions (FAQ)

What is the difference between GSM and Fabric Gauge?

GSM measures the mass per unit area, while Gauge (in knitting) refers to the number of needles per inch. While they are related, Gauge determines the 'fineness' of the fabric, while GSM determines the 'heaviness.' A supplier can use a high gauge but very thin yarns to reduce the GSM and save costs.

Is a higher GSM always better?

No. The 'better' weight depends on the end-use. A lightweight running shirt requires a low GSM (110-130) for breathability, while heavy-duty pants require a high GSM (300+). The danger lies in the *deviation* from the specified target, not the target itself.

How does fabric width affect weight verification?

If a fabric is 'over-stretched' to achieve a wider usable width (e.g. 60 inches instead of 58), the GSM will drop proportionally. Inspectors must measure the usable width and the weight simultaneously to ensure the supplier isn't trading thickness for width.

Can I perform fabric weight verification without a circular cutter?

Yes, but it is less accurate. You can cut a large rectangle (e.g., 1 meter by 1 meter) and weigh it on a standard scale. However, this is prone to cutting errors. The technical industrial standard is the 100cm2 circular cutter method for its repeatability.

What should I do if a batch is 8% lighter than specified?

An 8% variance usually indicates an intentional material shortcut. The technical response should be to conduct a 'Picks and Ends' count (ISO 7211) and a yarn denier test. If the construction is found to be deficient, the lot should be rejected as it will not meet the functional durability standards of the tech-pack.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.