In the high-performance landscape of industrial and professional power tools, reliability is not a luxury—it is a fundamental safety requirement. Power tools must operate under extreme mechanical loads, variable thermal conditions, and noisy electromagnetic environments. Engineering excellence in this sector is validated through three pillars of testing: Motor Aging protocols, Insulation Structural Safety, and Electromagnetic Compatibility (EMC). According to industry data, insulation failure remains a primary root cause for tool malfunction, with winding degradation accounting for over 50% of unexpected motor failures. By implementing rigorous quality control systems, manufacturers can identify latent material defects before they result in hazardous operational failures.

Key Takeaways

- Motor aging tests accelerate the life cycle of the tool to identify early bearing and winding wear.

- Insulation Resistance (IR) and Hi-Pot testing are critical to preventing electric shock and fire hazards.

- EMC compliance ensures tools operate without disrupting wireless signals or other electronic equipment.

- Environmental stress testing (heat, cold, humidity) is essential for tools used in outdoor or harsh industrial settings.

- Periodic quality inspections are necessary to verify that production units maintain the safety standards established during prototyping.

The Science of Motor Aging and Durability Testing

The electric motor is the heart of a power tool, and its longevity is governed by the laws of thermodynamics. Motor aging tests do not simply "run the tool"; they simulate years of service by stressing the insulation system and mechanical bearings. A common principle used is the Arrhenius Equation, which suggests that for every 10'C increase in operating temperature above the rated limit, the life of the motor insulation is halved. This makes thermal management a critical part of durability analysis.

Accelerated Life Cycle Assessment

Technical evaluation of motor health involves both energized and de-energized tests. During an energized test, the tool is operated under load in a controlled environment to monitor current draw, vibration profiles, and thermal rise. De-energized tests, such as surge testing, are used to detect inter-turn shorts in the windings that are invisible to standard resistance meters.

| Aging Test Method | Technical Objective | Failure Indicators |

|---|---|---|

| Load Endurance Cycle | Simulate continuous heavy-duty operation | Excessive heat, RPM drop, brush sparking |

| Surge / Impulse Test | Detect weak winding insulation | Waveform distortion, arc detection |

| Vibration Analysis | Evaluate bearing and shaft alignment | Mechanical noise, imbalance, resonance |

| Thermal Shock | Test expansion/contraction resilience | Housing cracks, winding delamination |

For manufacturers, comprehensive quality control must include a "burn-in" phase where a sample from each production lot is run under load to catch infant mortality defects in the electronic controllers and commutators.

Insulation Safety: Dielectric Strength and Leakage Analysis

Power tools are often handled in damp environments or used on conductive surfaces, making insulation integrity a matter of life and death. Modern tools utilize double insulation (Class II) or reinforced insulation systems to protect the user. The goal of insulation testing is to verify that the live parts of the motor are completely isolated from the tool's housing and user interface.

Hi-Pot (High Potential) Testing Protocols

The Hi-Pot test is the ultimate stress test for insulation. It involves applying a high voltage—typically 1000V plus twice the rated voltage—between the circuit and the frame. A failure is indicated if the leakage current exceeds a micro-ampere threshold or if a dielectric breakdown occurs. This test is mandatory under IEC 62841 and UL 1004 standards.

| Insulation Class | Maximum Operating Temp | Typical Materials |

|---|---|---|

| Class B | 130'C | Mica, Glass fiber, Polyester |

| Class F | 155'C | Advanced epoxy resins, Varnished glass |

| Class H | 180'C | Silicone elastomers, Polyimides |

In professional tool design, the "Creepage Distance" (the shortest path along the surface of an insulating material) and "Clearance" (the shortest distance through air) are calculated to prevent arcing under humid conditions. Regular quality assurance audits verify that these internal dimensions are maintained throughout the assembly process.

EMC Compliance: Managing Electromagnetic Noise

Power tools, especially those with brushed motors or digital controllers, act as transmitters of electromagnetic interference (EMI). EMC compliance ensures that the tool's "Emissions" (noise it sends out) are within limits and that its "Immunity" (resistance to incoming noise) is sufficient. Without compliance, a power tool could reset nearby computers, disrupt Wi-Fi signals, or even trigger other safety equipment accidentally.

Standards for Global Market Access

EMC testing is divided into two categories: Conducted and Radiated. Conducted emissions travel through the power cord back into the grid, while Radiated emissions travel through the air. In the EU, the EN 55014-1 standard dictates these limits for household appliances and power tools. In the US, FCC Part 15 regulates unintentional radiators.

- Conducted Emission: Evaluated using a LISN (Line Impedance Stabilization Network) to measure noise on the AC mains.

- Radiated Emission: Tested in a semi-anechoic chamber to measure radio frequency energy from 30 MHz to 1 GHz.

- Electrostatic Discharge (ESD): Testing how the tool handles a sudden 8kV or 15kV spark from the user's hand without malfunctioning.

Modern brushless motors (BLDC) require more complex EMC filtering because their high-speed switching controllers generate higher frequency noise than traditional brushed universal motors. Ensuring these tools meet EMC standards is a critical step in achieving CE and FCC marks.

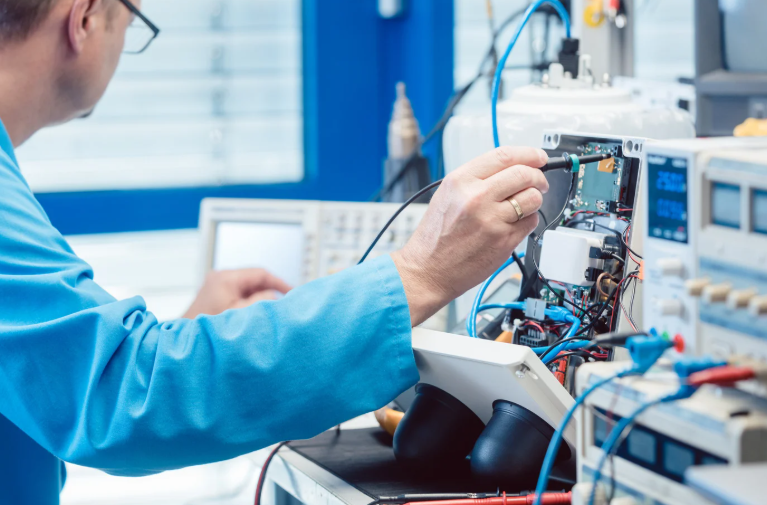

Integrated Quality Assurance for Power Tools

Reliability is achieved when testing is not an afterthought but integrated into the production management. A systematic manufacturing quality process involves checking raw material certificates (for the copper and magnets), performing in-process Hi-Pot tests on the stator/rotor, and conducting final functional and EMC audits on the finished assembly.

Effective factory audits are essential to ensure that the assembly line is protected from Electrostatic Discharge (ESD) and that testing equipment is calibrated to national standards. Predictive analytics can also be used to track batch failure rates, identifying trends that might indicate a bad shipment of bearings or faulty insulation varnish.

Maintenance Protocols for Tool Longevity

Even a tool that passes every factory test requires professional maintenance to maintain its safety profile. Professional users should follow these technical guidelines:

- Brush Inspection: For brushed motors, brushes should be replaced when they reach 50% of their original length to prevent commutator arcing.

- Ventilation Cleaning: Dust buildup in vents acts as insulation, trapping heat and accelerating the aging process of the motor windings.

- Cord Integrity: The power cord is the primary point of failure for insulation. Any nicks or "stress whitening" at the tool's entrance indicates a need for immediate replacement.

- Battery Management: For cordless tools, the Battery Management System (BMS) should be checked to ensure thermal sensors are active and cell balancing is functional.

By prioritizing tools that have undergone comprehensive Hardline Product analysis, buyers can ensure they are investing in equipment that provides a safe and productive work environment.

Frequently Asked Questions

What is the difference between an insulation resistance test and a Hi-Pot test?

An insulation resistance test (Megger) uses a standard DC voltage (usually 500V) to measure the resistance in Ohms. A Hi-Pot test uses a significantly higher voltage to see if the insulation physically breaks down or arcs. IR tells you how "good" the insulation is; Hi-Pot tells you if it's "safe."

Why do brushless motors last longer?

Brushless (BLDC) motors eliminate the physical contact between brushes and the commutator, which reduces friction, heat, and electromagnetic noise. This significantly slows the mechanical and thermal aging of the motor.

Does a tool with a CE mark automatically meet EMC requirements?

Yes, the CE mark indicates that the tool complies with all relevant European directives, including the EMC Directive (2014/30/EU) and the Low Voltage Directive (LVD).

Can I perform motor aging tests at home?

Standard home use is not an aging test. Factory aging tests involve specialized dynamometers to apply precise loads and environmental chambers to control heat and humidity. However, you can monitor your tool for "vibration changes" or "burning smells" as early indicators of aging.

What happens if a power tool is not EMC compliant?

Non-compliant tools can cause radio frequency interference, affecting television reception, cellular signals, and critical medical equipment. In some jurisdictions, operating or selling non-compliant electronic equipment can result in significant fines and product seizures.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.