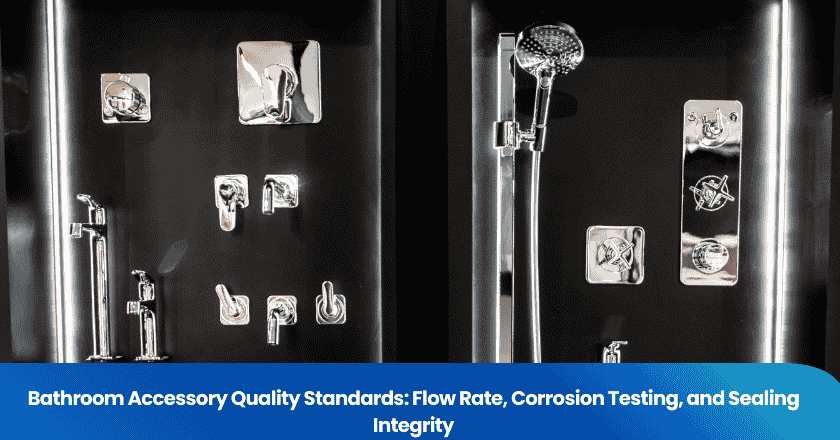

Technical excellence in bathroom accessory manufacturing is defined by three critical performance metrics: hydraulic flow efficiency, atmospheric corrosion resistance, and sealing structural integrity. In the sector of Hardline Products, rigorous quality control protocols are essential to ensure that faucets, showerheads, and valves meet international safety and conservation standards. By utilizing advanced laboratory testing—such as Neutral Salt Spray (NSS) analysis and high-pressure leakage cycles—manufacturers can mitigate the risks of premature failure and water wastage, providing professional buyers and consumers with reliable, long-lasting fixtures.

The Engineering of Hydraulic Flow Rates

Water flow rate, or volumetric discharge, is a primary indicator of a fixture's efficiency. Measured in Gallons Per Minute (GPM) or Liters Per Minute (LPM), it determines the user experience and the level of resource conservation. Modern engineering focuses on optimizing the aerator design to maintain a perceived high pressure while reducing actual water volume. This is governed by the ASME A112.18.1 / CSA B125.1 standards, which provide the technical framework for plumbing supply fittings.

Testing Protocols for Volumetric Discharge

Quality control teams utilize high-precision flow benches to measure performance across varying pressure points, typically from 20 psi to 80 psi. Key testing tools include:

- Digital Ultrasonic Flow Meters: These provide non-invasive, high-accuracy readings of water velocity without disrupting the flow profile.

- Aeration Efficiency Analyzers: These tools evaluate the air-to-water ratio within the stream, ensuring a "soft touch" feel that prevents splashing while saving water.

| Market Standard | Maximum Flow Rate (GPM) | Compliance Reference |

|---|---|---|

| Federal US Standard | 2.2 / 2.5 | EPAct 1992 |

| EPA WaterSense (Faucets) | 1.5 | Independent Certification |

| California Title 20 | 1.2 (Lavatory) / 1.8 (Shower) | CEC Regulations |

| European Union (Eco-Label) | Approx. 2.0 | Sustainability Directives |

The EPA's WaterSense program is particularly influential, requiring faucets to perform at 1.5 GPM at 60 psi while maintaining a minimum flow of 0.8 GPM at 20 psi. This ensures that even in homes with low municipal pressure, the fixture remain functional.

Electroplating Quality and Salt Spray Analysis

The bathroom environment is uniquely hostile to metal finishes due to constant humidity, temperature fluctuations, and exposure to cleaning chemicals. To ensure a tarnish-free lifespan, manufacturers rely on the Plating Salt Spray Test, primarily governed by the ASTM B117 standard.

Neutral Salt Spray (NSS) vs. CASS Testing

A standard NSS test involves exposing the accessory to a 5% Sodium Chloride (NaCl) solution at 35'C. However, for premium chrome finishes, the Copper-Accelerated Acetic Acid Salt Spray (CASS) test is often used, as it is more aggressive and better predicts the long-term durability of the nickel-chrome plating layers.

Technical Insight: A high-quality finish usually consists of three layers: a base layer of Copper for adhesion, a middle layer of Semi-bright and Bright Nickel for corrosion protection, and a final layer of Chrome for hardness and aesthetic luster.

| Test Parameter | NSS (ASTM B117) | CASS (ASTM B368) |

|---|---|---|

| NaCl Concentration | 50 +/- 5 g/L | 50 +/- 5 g/L |

| PH Level | 6.5 - 7.2 | 3.1 - 3.3 |

| Temperature | 35'C | 49'C |

| Common Duration | 24 - 200 Hours | 16 - 48 Hours |

After exposure, technicians evaluate the "Appearance Rating" (RA) and "Protection Rating" (RP). Any evidence of "pitting," "blistering," or "base metal corrosion" results in a failure of the quality inspection standard.

Sealing Integrity and Valve Cartridge Reliability

The core of any bathroom fixture is its valve or cartridge. Leak-proof sealing is not just about the initial installation; it is about maintaining a watertight barrier over hundreds of thousands of operations. Mechanical strength in sealing is verified through hydrostatic and pneumatic pressure testing.

Pressure Testing Protocols

Faucets and valves undergo a "Shell Test" where the body is pressurized to 1.5 times the maximum rated working pressure to check for casting defects or structural weaknesses. Subsequently, "Seat Tests" or "Closure Tests" verify that the internal seals prevent any bypass leakage.

- Dynamic Cycle Testing: Professional-grade cartridges are tested for 500,000 cycles (on/off and hot/cold transitions) without losing sealing performance.

- Torque Verification: Proper installation of the cartridge nut is critical; too little torque causes leaks, while too much can crack the ceramic disc or distort the O-rings.

| Seal Material | Technical Advantage | Application |

|---|---|---|

| EPDM Rubber | Excellent resistance to hot water and steam | Standard O-rings and Gaskets |

| Ceramic (Alumina) | Virtually wear-proof surface | High-end Valve Discs |

| Silicone | Maintain flexibility at extreme temperatures | Showerhead Nozzles |

| PTFE (Teflon) | Chemical inertness and low friction | Stem Seals and Ball Valve Seats |

Quality Control and Factory Auditing

For importers and brands, ensuring that these technical standards are consistently met requires robust quality control and assurance programs. A simple visual inspection is insufficient; technical validation is required at the factory level.

Conducting a factory audit allows businesses to verify that the manufacturer possesses the necessary calibrated testing equipment, such as Salt Spray Chambers and Spectrometers. Furthermore, key procedures for quality inspections should include a "Pull-off Test" for finishes and a "Cross-cut Adhesion Test" to ensure the electroplating will not peel under stress.

Buyer's Checklist for High-Performance Accessories

To avoid the hidden costs of leakage and corrosion, technical buyers should prioritize the following specifications:

- Material Composition: Prefer solid DZR (Dezincification Resistant) brass or Grade 304/316 stainless steel over zinc alloys.

- Surface Finish Thickness: Look for at least 8-10 microns of Nickel and 0.25 microns of Chrome.

- Aerator Quality: High-end aerators from recognized brands prevent limescale buildup and maintain flow consistency.

- Certification Marks: Ensure products carry the UPC, NSF/ANSI 61 (for lead-free compliance), and WaterSense marks.

Choosing accessories that have been subjected to rigorous Hardline Product testing ensures that the fixtures will perform as intended for their projected 10-15 year lifespan, even in the most demanding residential or commercial environments.

FAQ

What is the primary cause of faucet leaks?

Most leaks are caused by the degradation of internal seals (O-rings) or the wear of the valve cartridge. Using high-purity ceramic discs and EPDM seals significantly extends the leak-proof period of the fixture.

How can I identify a lead-free bathroom faucet?

Look for the NSF/ANSI 61 and NSF/ANSI 372 certifications. These standards verify that the wetted surfaces of the plumbing fixture contain less than 0.25% lead, making them safe for potable water contact.

Does a low flow rate mean low water pressure?

Technically, no. Flow rate is the volume of water, while pressure is the force. High-quality fixtures use aerators to increase water velocity and mix air into the stream, creating a high-pressure sensation while using significantly less water.

Why do some chrome finishes turn green or peel?

This is usually due to "pitting corrosion" where the outer chrome layer is too thin or porous, allowing moisture to reach the brass or zinc base metal. A failed salt spray test during the production phase would typically identify this manufacturing defect.

What is the benefit of a whole house water filter for accessories?

Sediment and hard minerals (Calcium/Magnesium) can clog aerators and scratch ceramic valve discs. A filtration system protects the internal mechanics of your bathroom accessories, maintaining the intended flow rate and preventing leaks.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.