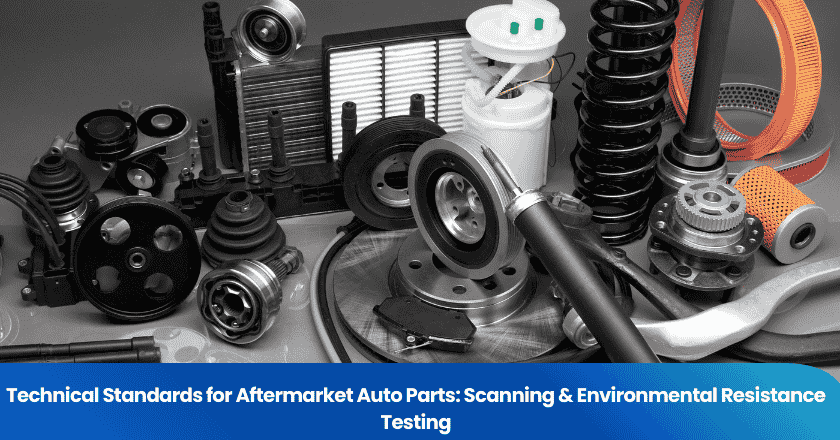

In the global automotive supply chain, Aftermarket Auto Parts serve as critical alternatives to Original Equipment Manufacturer (OEM) components. However, the viability of these parts depends entirely on their ability to achieve dimensional interchangeability and functional fidelity. Industrial-grade validation protocols, ranging from high-resolution 3D scanning to intensive thermochemical resistance testing, are employed to ensure that components—from engine gaskets to complex suspension assemblies—meet or exceed the rigorous safety standards of the automotive industry. As vehicle systems become more technologically advanced, the reliance on precise geometric verification and material endurance testing has become the baseline for mechanical reliability and consumer safety.

Key Takeaways

- Dimensional accuracy scanning (CMM and 3D) ensures seamless integration with existing OEM systems.

- Heat and oil resistance testing (ASTM D471) prevents the premature degradation of polymer and elastomer components in engine environments.

- IATF 16949 and ISO 9001 certifications serve as primary technical filters for selecting reliable aftermarket vendors.

- Advanced metrology techniques like CAT scans are used to identify latent internal casting defects.

- Regular manufacturing quality inspections and PPAP (Production Part Approval Process) are essential for consistent batch quality.

- Traceability through Material Test Reports (MTR) ensures compliance with global safety regulations and warranty standards.

The Metrology of Aftermarket Precision: Dimensional Accuracy Scanning

Precision is the absolute requirement for any aftermarket component. Even a deviation of 0.1mm in a cylinder head gasket or a control arm bushing can lead to catastrophic mechanical failure or accelerated wear on adjacent systems. Modern metrology leverages both contact and non-contact scanning technologies to generate high-density point cloud data, which is then compared against the original CAD (Computer-Aided Design) model.

3D Laser Scanning vs. Coordinate Measuring Machines (CMM)

While traditional calipers and micrometers are used for basic checks, industrial-grade dimensional inspections utilize CMM for high-tolerance internal features and 3D laser scanners for complex external surface profiles. Laser scanners utilize triangulation or structured light to capture millions of data points per second, allowing for "Full-Surface Inspection" that can detect warping or surface irregularities invisible to the naked eye.

| Metrology Tool | Technical Principle | Accuracy Limit | Primary Application |

|---|---|---|---|

| Bridge CMM | Tactile Ruby-tip Probe | +/- 0.001mm | Engine bores, transmission shafts |

| 3D Laser Scanner | Blue Light Triangulation | +/- 0.025mm | Body panels, intake manifolds |

| CT (CAT) Scan | X-Ray Tomography | Voxel-based resolution | Internal casting voids, porosity analysis |

| Handheld Scanner | Structured Light | +/- 0.050mm | On-site assembly fit-checks |

Environmental Stress Testing: Heat and Thermochemical Resistance

The automotive engine compartment is one of the most hostile environments for materials. Components must operate consistently while cycling between ambient winter temperatures and internal temperatures exceeding 150'C. Furthermore, these parts are constantly exposed to engine oils, hydraulic fluids, and aggressive fuels that can trigger chemical degradation or polymer swelling.

ASTM D471: Fluid Immersion Dynamics

For seals, hoses, and gaskets made of elastomers (like Nitrile/NBR or Viton/FKM), manufacturers conduct Oil Resistance Testing according to ASTM D471. This involve immersing the material in standard IRM oils for 70 to 168 hours at elevated temperatures. Engineers measure the "Swelling Kinetics"—the percentage change in volume and hardness. A high-quality aftermarket seal must maintain a swell rate within 5-10% to ensure sealing pressure is not lost during the vehicle's service life.

| Environmental Stressor | Testing Protocol | Failure Indicators |

|---|---|---|

| Thermal Cycling | -40'C to 125'C (500 cycles) | Stress cracking, delamination |

| Oil Immersion | ASTM D471 (Hot Oil 150'C) | Solubility, excessive softening |

| Compression Set | ASTM D395 | Permanent deformation, loss of seal |

| Corrosion (Salt Mist) | ISO 9227 (NSS) | Oxidation, galvanic corrosion |

The Role of IATF 16949 and PPAP in Quality Assurance

Technical buyers and importers do not rely on visual inspection alone. They look for compliance with IATF 16949, the international standard for automotive quality management systems. This standard emphasizes defect prevention and the reduction of variation and waste in the supply chain. A key component of this is the Production Part Approval Process (PPAP).

During a factory audit, the implementation of PPAP is scrutinized. This 18-element process ensures that the manufacturer has a complete understanding of the design requirements and can consistently produce parts that meet these criteria during actual production runs at the quoted rate. Key elements include:

- FMEA (Failure Mode and Effects Analysis): Identifying potential failure points in the manufacturing process before they occur.

- MSA (Measurement Systems Analysis): Verifying that the scanning and measurement tools themselves are accurate and repeatable.

- Control Plan: A detailed technical document outlining how every critical dimension and material property will be monitored during mass production.

Material Science: Selecting the Right Alloys and Polymers

Reliable Aftermarket Auto Parts must utilize materials that replicate or exceed the properties of the OEM counterparts. Quality control involves "Gravimetric Analysis" and "Differential Scanning Calorimetry" (DSC) to verify material purity. For metallic components, hardness testing (Rockwell or Brinell) is mandatory to ensure structural load-bearing capacity.

- Cast Iron/Steel: Must be checked for "Nodularity" and "Grain Structure" to prevent brittle fracture under vibration.

- Engine Gaskets: Must utilize reinforced fiber or multilayer steel (MLS) to resist blow-through under high combustion pressures.

- Radiator Hoses: Must be made of Electrochemical Degradation (ECD) resistant EPDM to prevent internal cracking caused by coolant ions.

Effective quality assurance requires third-party laboratory verification to confirm that the NBR used in a fuel hose is truly fuel-grade and not a lower-cost industrial substitute that will disintegrate within six months of use.

Practical Guide for Professional Buyers

When sourcing Aftermarket Auto Parts, a technical checklist can mitigate the risk of procurement failure. Organizations should integrate these steps into their standardized quality control procedures:

- Request the ISIR (Initial Sample Inspection Report): This document provides 100% measurement data for the first samples produced from the mass-production tooling.

- Verify Batch Traceability: Every component should have a date code or batch stamp to allow for targeted recalls if a material defect is identified.

- Assess Surface Finish (Ra Value): For parts involving friction or sealing, measuring the surface roughness is critical. A part can be dimensionally perfect but functionally useless if the surface finish is too coarse.

- Conduct Cross-Sectional Analysis: For high-stress parts like brake rotors or engine valves, cutting a sample to inspect for internal voids or improper heat-treatment depth is a necessary destructive test.

By prioritizing parts that have undergone rigorous product inspections, buyers can ensure they are providing components that safeguard the mechanical integrity and long-term safety of the vehicles they service.

Frequently Asked Questions (FAQ)

What is the difference between OEM and Aftermarket Auto Parts?

OEM parts are made by the vehicle's manufacturer or their direct contractor using the original blueprints. Aftermarket parts are produced by third-party companies. While some aftermarket parts are of lower quality, many "Certified Aftermarket Parts" meet or exceed OEM specifications through rigorous testing.

Why is CMM better than 3D scanning for engine parts?

CMM (Coordinate Measuring Machine) uses physical probes that can reach deep into engine bores and recesses where laser light might be blocked. CMM also offers significantly higher accuracy (micron-level) required for the critical tolerances of combustion and transmission systems.

What does the "Compression Set" test measure?

The compression set test (ASTM D395) measures the ability of a gasket or O-ring to return to its original thickness after being squeezed for a long time under heat. If a material has a high compression set, it will "flatten" permanently, leading to a leak in the engine or cooling system.

How can I verify if an aftermarket part is CAPA certified?

Certified parts will carry a CAPA (Certified Automotive Parts Association) seal on the packaging and often a unique QR code or serial number on the part itself. CAPA certification ensures that the part has passed independent dimensional and material audits.

Does a 3D scan report guarantee the part will fit?

A 3D scan verifies the "Form" of the part, but "Fit" and "Function" also depend on material properties and internal tolerances. A comprehensive quality report should include the 3D scan alignment results (color maps) alongside material hardness and compression test data.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.