In the technical domain of Softline Products, fasteners represent the most frequent point of mechanical failure. For high-performance garments, heavy-duty luggage, and professional footwear, the structural fidelity of the closure system is non-negotiable. Zipper fatigue testing serves as the definitive industrial validation for reciprocating endurance, quantifying the fastener's ability to maintain its interlocking function under cyclic kinetic stress. A zipper that appears robust during initial sampling may suffer from metal embrittlement, polymer abrasion, or tape fraying after thousands of operations. By adhering to international benchmarks such as ASTM D2061 and ISO 16181, manufacturers can mitigate the astronomical costs of product recalls and safeguard their brand reputation through empirical quality assurance.

Key Takeaways

- Fatigue testing simulates accelerated product lifecycles to identify latent failure modes in sliders and chain elements.

- Industrial standards (e.g., 5,000 cycles) differentiate between consumer-grade and professional-grade fasteners.

- Metrological checks focus on 'Crosswise Strength' and 'Stop Integrity' to prevent catastrophic chain separation.

- Material selection—zinc alloy vs. plastic vs. nylon—dictates the thermal and friction-induced wear rates during testing.

- Professional apparel quality control must include 'In-Line' audits to prevent material substitution in mass production.

- Digital real-time reporting via quality assurance protocols ensures traceability and transparency for global buyers.

The Physics of Fastener Fatigue: Stress and Wear Dynamics

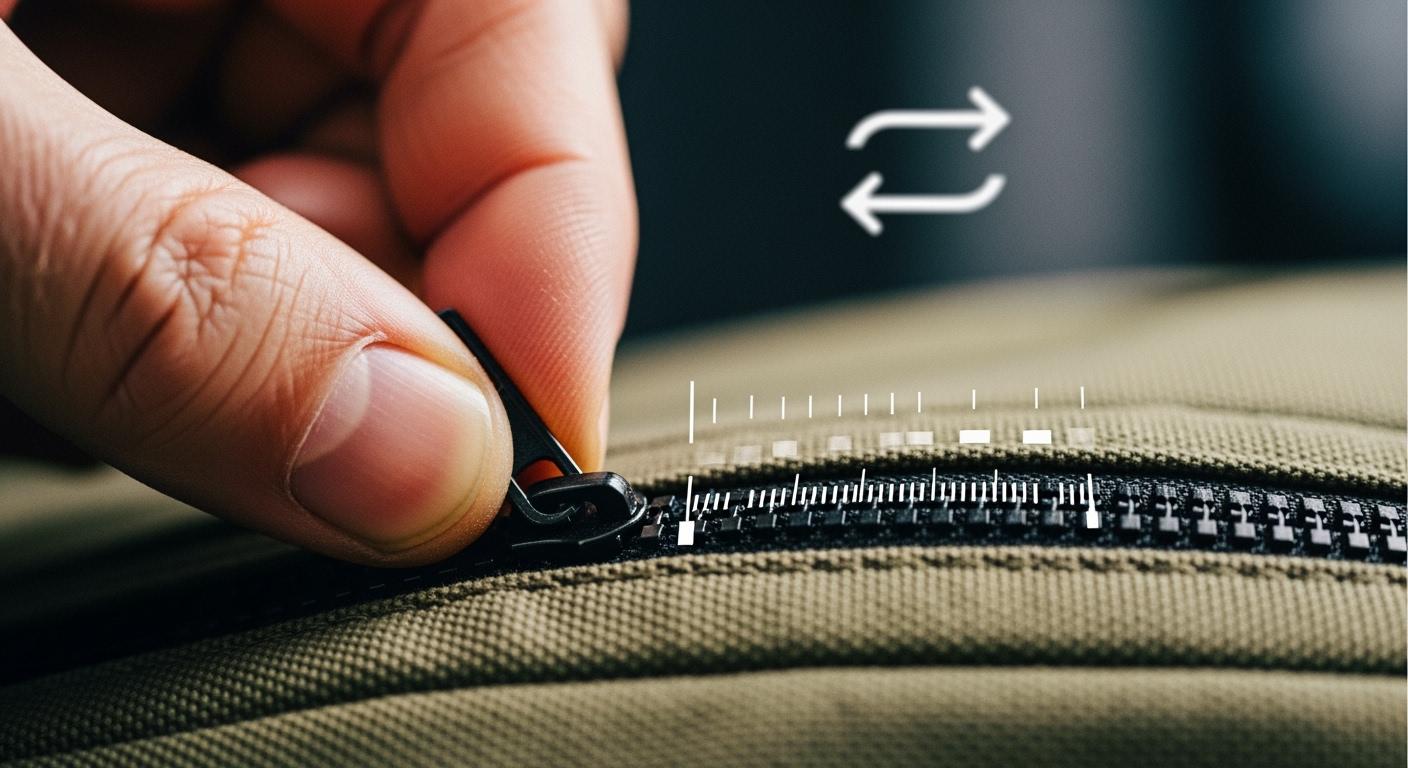

A zipper is a mechanical assembly involving complex interactions between the slider, the interlocking teeth (elements), and the textile tape. During the Opening/Closing cycle, the slider's internal 'flanges' apply lateral force to the teeth to initiate engagement. This generates localized friction and heat. In a professional quality assurance program, the objective of the 5,000-cycle test is to determine the 'Wear Margin'—the threshold where the dimensions of the teeth or the slider cavity change enough to compromise the interlocking force.

Molecular Stress and Plastic Deformation

For molded plastic zippers, fatigue primarily manifests as 'Polymer Chain Scission' due to repeated flexing. For metal zippers (Brass or Zinc Alloy), the concern is 'Work Hardening,' where the material becomes brittle and eventually fractures. Testing at a standardized frequency of 30 cycles per minute prevents 'Excessive Heat Buildup,' which could artificially soften the materials and lead to false-positive results that would fail in real-world ambient conditions.

| Fastener Type | Material Property Focus | Common Failure Mode | Typical Application |

|---|---|---|---|

| Nylon Coil | Filament Elasticity | Helix deformation / Bursting | Sportswear, sleeping bags |

| Molded Plastic | Impact Resistance | Tooth shear / Slider fracture | Outdoor jackets, workwear |

| Brass / Metal | Tensile Strength | Work hardening / Tape fraying | Denim, high-end luggage |

| Waterproof (Coated) | Laminate Adhesion | Membrane peeling / Stiff pull | Technical gear, scuba bags |

International Testing Standards for Zipper Integrity

Consistency in fastener quality is achieved through adherence to tiered testing protocols. While 5,000 cycles is the standard benchmark for quality assurance, specialized items like firefighter gear or aeronautical equipment may require 20,000+ cycles. The industry relies on two primary standard families: the American ASTM D2061 and the European/International ISO 16181 (formerly BS 3084).

ASTM D2061 vs. BS 3084: Technical Frameworks

ASTM D2061 provides a comprehensive metrological approach, measuring the force required for 'Element Pull-off' and 'Slider Deflection.' BS 3084 categorizes zippers into 'Performance Codes' (A, B, C, D) based on their application, with 'Grade D' representing the highest strength for industrial use. During consistency audits, inspectors must verify that the test parameters (load weight and stroke length) match the intended performance grade.

| Performance Grade | End-Use Requirement | Min. Crosswise Strength |

|---|---|---|

| Light (Code A) | Fine lingerie, delicate silks | 150 N |

| Medium (Code B) | Standard shirts, light pants | 250 N |

| Medium-Heavy (Code C) | Jackets, luggage, backpacks | 450 N |

| Heavy (Code D) | Protective gear, tents | 600 N+ |

Technical Standard Alert: For safety-critical zippers, the 'Top Stop Holding Strength' must be tested *after* the 5,000-cycle fatigue run. This ensures the slider won't fly off the track if a consumer pulls it aggressively at the end of the garment's lifecycle.

The Industrial Workflow of a Fatigue Validation

To produce repeatable data, the quality inspection process must follow a precise technical sequence. The zipper is not tested in isolation but is often mounted on a substrate that mimics its final installation environment.

Sample Preparation and Machine Calibration

- Substrate Tension: The zipper tape is clamped with a lateral tension (usually 10N-15N) to simulate the 'bursting' force of a loaded bag or a tight garment.

- Reciprocating Stroke: The machine is set to a 75mm +/- 2mm stroke length to ensure the slider traverses a sufficient section of the chain.

- Lubrication Audit: Testing is performed on 'as-received' samples. Any addition of waxes or oils to mask a 'stiff pull' during testing is a violation of protocol and will result in a failed audit.

Integrating Fatigue Tests into the Manufacturing Lifecycle

Consistency is achieved by building quality into the 'Pre-Production' and 'In-Line' phases. Relying solely on a final audit is a high-risk strategy that often leads to entire batch rejections. A technical softline quality assurance strategy includes:

- PPI (Pre-Production): Validating the 'Element Separation Force' of the raw zipper batch *before* it is sewn into garments.

- DPI (During Production): Pulling random samples from the assembly line after 'Top-Stopping' to check for mechanical damage to the tape.

- PSI (Pre-Shipment): Final random sampling (AQL 1.0 or 1.5) for fatigue durability to confirm that no 'material shortcuts' were taken during the production run.

Effective quality management uses these data points to identify 'Lot Variance.' If the first 500 units pass at 5,000 cycles but the last 500 units fail at 3,000, it indicates a deterioration in the factory's tooling or a shift in the raw material source.

Real-Time Reporting and Decision-Making

Modern quality assurance utilizes digital platforms to provide immediate 'Line-of-Sight' into the testing lab. Inspectors upload 360-degree photos and videos of the testing counter directly from the factory floor. This real-time transparency allows global buyers to monitor 'Fastener Performance' and intervene instantly if a technical discrepancy is identified. Digital logs provide 'Process Traceability,' which is essential for compliance with the Consumer Product Safety Improvement Act (CPSIA) in the United States.

Conclusion: Establishing Fastener Reliability Standards

The zipper is often the 'weakest link' in high-value products. A failure here renders the entire item functionally useless, leading to customer dissatisfaction and high return rates. By integrating standardized reciprocating cycle testing with rigorous in-process audits, manufacturers can ensure their fasteners maintain exceptional performance throughout the product's intended lifespan. Transparency in these technical processes builds consumer trust and differentiates premium brands in a crowded global marketplace.

Frequently Asked Questions (FAQ)

What is the difference between a static pull test and a fatigue test?

A static pull test measures the 'Ultimate Strength' (breaking point) of a zipper in a single event. A fatigue test measures 'Endurance'—the ability to withstand thousands of smaller loads over time. A zipper can pass a pull test but fail a fatigue test if the teeth wear down too quickly.

Why is 5,000 cycles the standard number?

Through industrial research, 5,000 cycles have been identified as the threshold representing roughly 2-3 years of intensive consumer use. For products with a shorter intended life (e.g. promotional items), 500-1,000 cycles may be acceptable, but premium brands never go below the 5,000-cycle technical baseline.

Does a metal zipper always last longer than a nylon one?

Not technically. While metal teeth have higher tensile strength, nylon coil zippers are often more 'Flexible' and can handle 'Misalignment' during the fatigue cycle better than rigid metal element. The 'Better' fastener depends entirely on the substrate and the expected load.

What is 'Slider Locking Strength'?

This is a technical test to ensure the slider remains in its fixed position and doesn't 'Auto-Open' under the weight of the garment or movement. The lock must resist a minimum force (typically 25N-40N) to pass industrial standards.

How can I identify 'Quality Fade' in my zipper shipments?

Monitor the 'Element Weight' and 'Tape Thickness' of bulk goods against the approved golden sample. If a vendor uses 10% less metal or a lighter polyester tape to save costs, the fatigue life will drop proportionally. Regular standardized inspections are the only reliable way to catch these discrepancies.

Grow your business with TradeAider Service

Click the button below to directly enter the TradeAider Service System. The simple steps from booking and payment to receiving reports are easy to operate.