Quality control (QC) plays a vital role in ensuring the durability and performance of both finished items like notebooks and industrial paper materials. Reliable paper must meet strict standards for grammage, whiteness, and binding strength. These parameters help manufacturers produce stock that meets customer needs and industry requirements. High-level inspections protect brand reputation and improve user satisfaction. Consistent evaluation reduces the risk of defects and supports the long-term success of any paper-based business.

Key Takeaways

- Understanding grammage (GSM) is crucial for selecting the right paper. Higher GSM indicates thicker, stronger sheets suitable for covers and packaging.

- Whiteness affects both the appearance and usability of paper. Bright white paper enhances brand image and print clarity, while natural-looking paper appeals to eco-conscious consumers.

- Regular testing of binding strength ensures durability. Strong binding prevents pages from falling out, enhancing product reliability.

- Implementing strict quality checks reduces defects and improves customer satisfaction.

- Using proper tools like grammage checking kits and whiteness meters is essential for accurate quality control.

Why Paper Product QC Matters

Key Quality Parameters

Paper product QC focuses on three main quality parameters: GSM, whiteness, and binding strength. These factors determine how well paper performs in real-world situations. The GSM (grams per square meter) measures the weight and density of paper. This value helps manufacturers select the right material for each application. For example, a higher GSM means thicker and stronger sheets, which work well for covers or packaging. Lower GSM values suit lightweight printing or tissue products.

| Category | Grammage (GSM) |

|---|---|

| Paper | Up to 200 |

| Paperboard | 200 and above |

Whiteness affects both the appearance and usability of paper. The CIE Whiteness measurement describes how much light the paper reflects, which impacts readability and visual appeal. Binding strength ensures that notebooks, books, and other bound products stay intact during use.

Common quality failures in finished paper goods and industrial materials include:

- Using the wrong paper grade, which can cause tearing or wear.

- Overlooking storage conditions, leading to warping or mold.

- Ignoring compatibility with machines, resulting in jams.

- Missing defects due to poor inspection protocols.

Impact on Performance and Compliance

Paper product QC directly influences product reliability and customer satisfaction. When companies follow strict quality checks, they reduce product loss and improve efficiency. Customers trust brands that deliver consistent results. Appropriate GSM and whiteness levels help prevent shipping damage and lower transportation costs.

| Property | Effect on Performance |

|---|---|

| Grammage | Affects strength and thickness, influencing durability and suitability for various uses. |

| Whiteness | Impacts appearance and usability, shaping consumer perception. |

| Binding Strength | Ensures durability, especially in packaging and printing applications. |

International standards such as ISO 536 for GSM and ISO 534 for thickness guide these checks. Regulations like EU (EC) 1935/2004 and US FDA 21 CFR 176.170 set requirements for food contact materials. Labels must include safety information and usage instructions to meet compliance rules.

Grammage (GSM) in Paper Product QC

What Is Grammage (GSM)?

Grammage, often called GSM, stands for grams per square meter. This value measures the weight of paper over a one-square-meter area. It serves as an internationally accepted standard for comparing different types of paper. The GSM value helps define both the thickness and weight of a sheet. In paper product QC, GSM plays a key role in determining characteristics such as durability and print quality.

Manufacturers use GSM to select the right material for each application. Lightweight papers, such as those around 80 GSM, work well for flyers and everyday printing. Magazines often use paper in the 120-160 GSM range. High GSM papers, like 400 GSM boards, are chosen for luxury packaging or business cards. Lighter options provide flexibility and easy folding, while heavier papers offer more durability and a premium feel.

Accurate Paper GSM Measurement

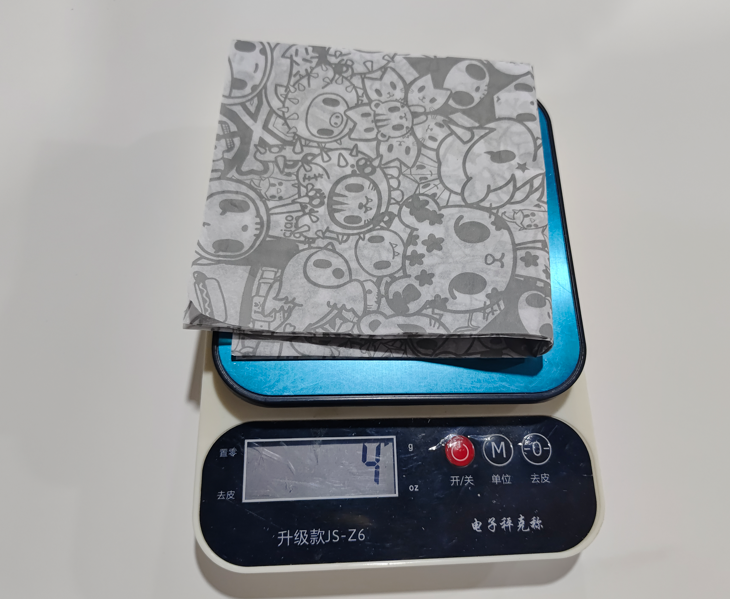

Accurate measurement ensures that every batch meets the required specifications. QC relies on precise tools and methods to achieve this. The most common laboratory testing equipment includes a GSM round cutter and a digital balance. The round cutter creates a sample of exact size, while the high-precision balance measures the sample's weight.

| Component | Description |

|---|---|

| GSM Round Cutter | A circular sample cutter with a sharp stainless-steel blade for precise cutting of paper samples. |

| Digital GSM Balance | A high-precision weighing balance designed for accurate measurements with a user-friendly interface. |

| Features | Lightweight, sturdy build, air-proof hood, stable weighing plate for precise calculations. |

Using a standardized checking kit ensures repeatable results. The digital balance provides accurate readings, which are essential for quality control. Laboratory testing equipment must be calibrated regularly to maintain precision.

Grammage Testing Steps

Grammage testing follows a clear process to guarantee reliable results:

- Sample Preparation: Condition the paper sample according to standards like ISO 187 or ASTM D685. Cut a sample with a round cutter to ensure the area is precise.

- Weighing the Sample: Use a high-precision weighing balance. Tare the balance, place the sample gently, and record the weight.

- Calculation: For a 100 cm² sample, calculate GSM using the formula: GSM = Weight (g) x 100.

- Record Results: Write down the sample's dimensions, weight, and calculated GSM. Repeat the process for at least three samples to ensure accuracy.

Tip: Always use a calibrated grammage checking kit for consistent results.

Whiteness Verification in Paper QC

Whiteness and Product Appearance

Whiteness plays a major role in how people perceive paper products. Bright white paper often signals hygiene, purity, and high quality. Many brands choose bright white paper to create a professional image, as it makes printed logos and graphics look more vibrant. Conversely, matte brown paper gives a sense of authenticity and sustainability, appealing to eco-conscious consumers.

Visual and Instrumental Whiteness Checks

Paper product QC uses both visual and instrumental methods. Visual checks involve comparing paper samples under controlled lighting to spot color consistency and surface defects. Instrumental testing uses devices that measure light reflectance. These devices often use RGB LEDs to check color accuracy and detect optical brightening agents (OBAs).

| Method | Light Source | Key Application | Special Features |

|---|---|---|---|

| Red, Green, Blue | RGB LEDs | Color accuracy & OBA detection | Portable, instant results |

| Blue Light | Blue LED | Bluish whiteness assessment | Works in dark environments |

| Blue + UV Light | Blue + UV | Fluorescence measurement | Wet/dry testing compatibility |

| Blue + Green Light | Blue + Green | Brightness agent monitoring | Temperature resistant |

Ensuring Consistent Whiteness

Manufacturers must keep whiteness consistent across all batches. They use portable spectrophotometers for quick checks and benchtop units for detailed lab measurements. Controlled lighting cabinets help inspectors compare samples under standardized conditions.

| Type of Paper | Whiteness Range (%) |

|---|---|

| Book Paper | 55% – 75% |

| Newsprint | 45% – 52% |

| Offset Color Printing Paper | 77% – 87% |

| Coated Color Printing Paper | 80% – 85% |

Following international standards such as CIE Whiteness and ISO 2469 ensures that every batch meets the required quality.

Binding Strength and Durability Testing

Binding Strength in Paper QC

Binding strength plays a key role in the durability and usability of paper products. Books, notebooks, and other bound items must stay together during daily use. Different binding methods offer unique advantages and challenges.

| Binding Method | Advantages | Disadvantages |

|---|---|---|

| Singer Sewn Binding | Durable, attractive, creative | Requires sewing machinery, slower process |

| Case Binding | Extremely durable, premium look | Expensive, heavy |

| Spiral Binding | Flexible, lays flat | Less durable with heavy handling |

| Coil Binding | Opens fully, durable | Can deform under pressure |

Functional and Mechanical Testing

Paper quality control teams use both functional and mechanical tests to check binding strength. These tests help confirm that products meet durability standards.

| Test Type | Purpose | Methodology |

|---|---|---|

| Pull Test | Measures force needed to pull a page from the spine | Force measured in Newtons (N) |

| Flex Test | Checks page turning durability | Simulates repeated use cycles |

Addressing Binding Failures

Binding failures can occur due to various reasons. Poor paper absorption can affect how well glue adheres. Environmental factors like low temperatures can slow glue drying, while high humidity can weaken bonds. Common causes include:

- Poor absorption needing better adhesives.

- Varnishes creating non-stick surfaces.

- Dust, oil, or moisture contamination.

- Incorrect glue selection or insufficient pressing force.

| Factor | Description |

|---|---|

| Ambient Temperature | Changes glue performance if outside range. |

| Adhesive Temperature | Must stay within set range for optimal bonding. |

| Surface Condition | Rough or dirty surfaces block adhesion. |

Tip: Regular binding strength testing helps maintain product reliability and supports compliance with industry standards.

Effective paper product QC relies on clear steps: verify GSM, check whiteness, and test binding strength. Regular audits and standardized procedures help manufacturers meet client needs and reduce defects.

| Improvement Metric | Percentage Change |

|---|---|

| Defects Reduced | 30% |

| Tensile Strength Improved | 20% |

| Customer Complaints Cut Down | 50% |

FAQ

What does grammage (GSM) mean in printing?

Grammage (GSM) refers to the weight of paper per square meter. Printers use GSM to choose the right paper for specific jobs. Higher GSM often means thicker sheets, which can improve printing durability and feel.

How does whiteness affect printing quality?

Whiteness impacts how colors appear on paper. Brighter paper makes images and text look sharper and more vibrant. Consistent whiteness helps maintain print clarity across different production batches.

Why is binding strength important for printing products?

Binding strength keeps pages together in books and notebooks. Strong binding prevents pages from falling out during use, ensuring the product remains functional and durable over time.

How do inspectors check printing quality during paper selection?

Inspectors examine samples for defects, color consistency, and surface smoothness. They use tools to measure GSM and whiteness to ensure the paper meets the required specifications before printing begins.

Развивайте свой бизнес с услугами TradeAider

Нажмите кнопку ниже, чтобы войти непосредственно в систему услуг TradeAider. Простые шаги от бронирования и оплаты до получения отчетов легко выполнить.